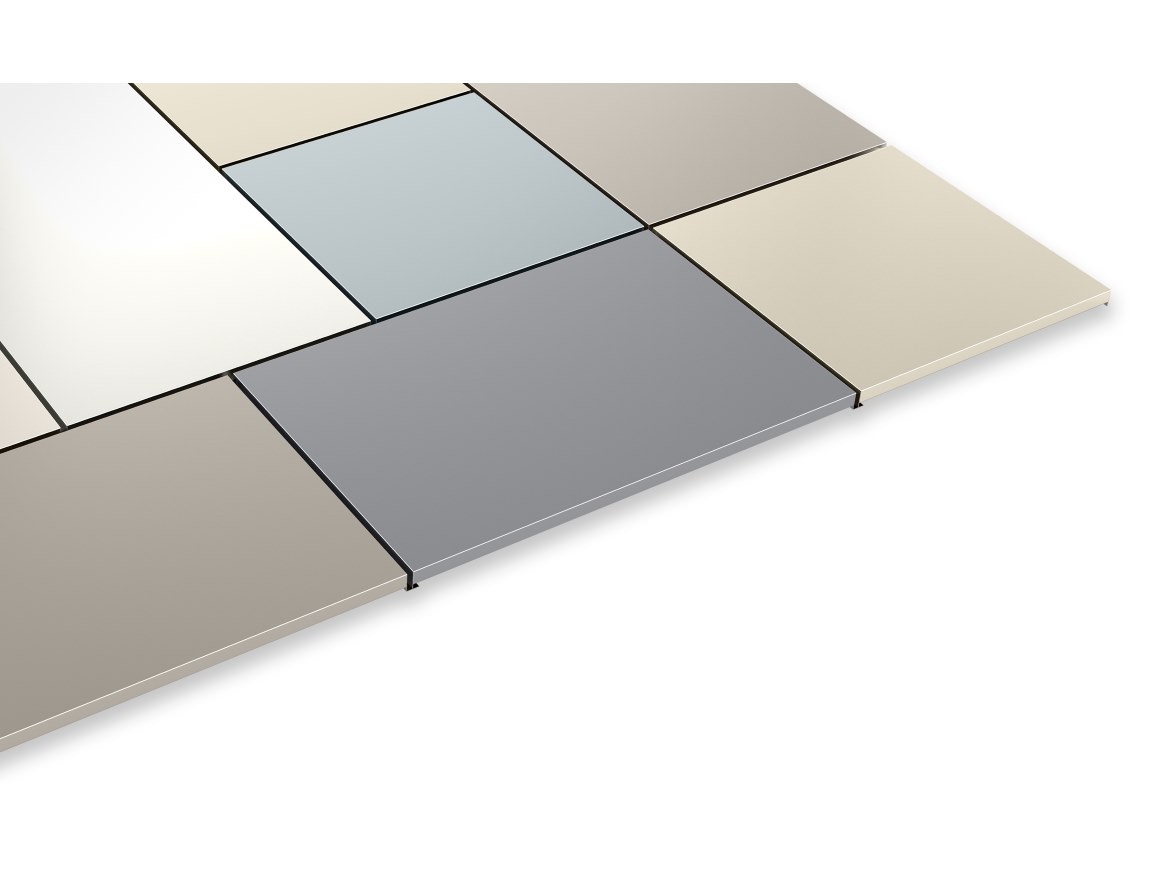

The new PAC-CLAD Modular AL wall panel system from Petersen empowers architects and designers to create unique metal cladding surfaces using panels of various sizes and depths and in multiple colors. Designers can choose standard panel dimensions or can define dimensions and depths to create truly unique, flexible and eye-catching patterns.

Vertical or horizontal panels of varying sizes and depths can be combined on the same layout in cassette-style patterns. Modular AL panels can be finished in any combination of the 46 standard PAC-CLAD colors plus custom colors. Panels can be perforated, including in patterns that spell words, form logos, shapes or images. Installation of Modular AL panels can be performed on a variety of substrates including plywood, insulation, purlins or any combination.

“Architects have demonstrated amazing design creativity with our existing wall panels, so we’re turning them loose with this Modular AL panel system so they can stretch their imagination even further,” says Mike Weis, Petersen’s vice president, sales and marketing. “This panel system is so versatile with nearly unlimited combinations of patterns, and we’re excited to see the designs that architects create. They’re going to love it. Petersen continues to expand design capabilities by introducing metal panel systems that architects and designers need to maximize their creative skills.”

Features of the Modular AL panel system include surfaces that can be flat or tapered, a concealed fastener system, weep holes for pressure and moisture venting, and installation without sealants. Full fabrication packages are available on all projects to which Modular AL panels are applied. Modular AL panels are made of 100% recycled aluminum. All PAC-CLAD colors come with a 30-year finish warranty.

Modular AL panels are available in .050, .063 and .080 aluminum. Panel depth can range from 1 3/8-in. to 3-in., while the width of joints between panels can range from 1/2-in. to 1-in. Modular AL panel assemblies meet the following test standards: E283, E331, E330 and AAMA 508.

Length, Width, Depth Can Change for New Modular AL Wall System

Modular AL