Today’s building design and construction professionals are increasingly being called upon to specify products that both meet environmental performance and building safety requirements and promote long-term resiliency—a balance that can be challenging to achieve. The good news is that green building trends are driving greater demand for third-party verified information. American Wood Council (AWC) technical publications embrace a simplified yet science-driven approach to understanding the potential environmental impact of building products.

While some environmentally-conscious builders do their own research to guide the selection of building products based on environmental performance, this can be a daunting and time-intensive process depending on the size and scope of the project. To help alleviate this, environmental product declarations (EPDs) are playing a larger role in simplifying these decisions.

Simply put, EPDs are standardized tools that provide information about the potential environmental impacts of the products they cover. They have established credibility and worldwide applicability for measuring the impact of building materials across a phase or their entire lifecycle. Based on life-cycle assessments (LCA), EPDs describe everything from resource consumption and energy use, to global warming potential, air emissions, soil, water and waste generation.

Simply put, EPDs are standardized tools that provide information about the potential environmental impacts of the products they cover. They have established credibility and worldwide applicability for measuring the impact of building materials across a phase or their entire lifecycle. Based on life-cycle assessments (LCA), EPDs describe everything from resource consumption and energy use, to global warming potential, air emissions, soil, water and waste generation.

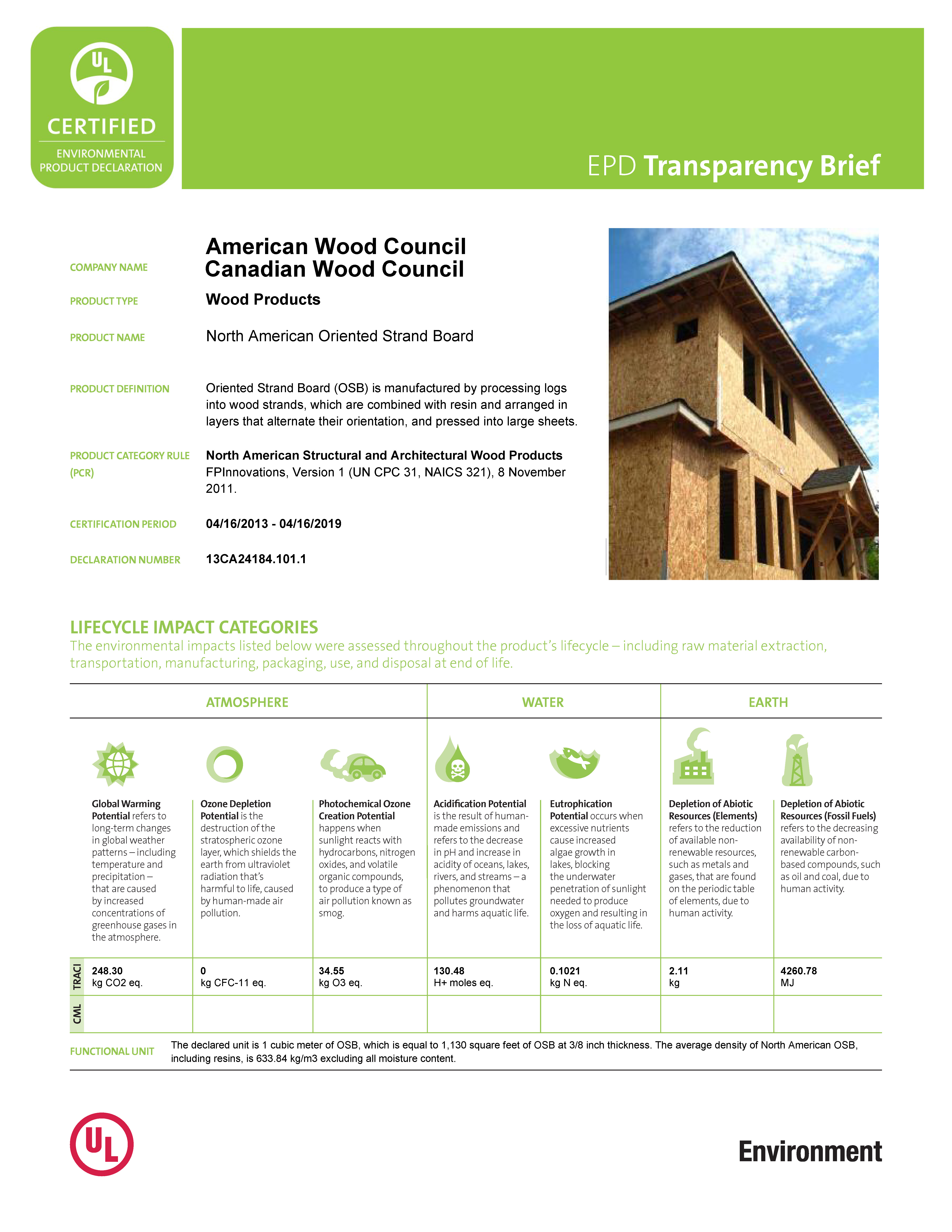

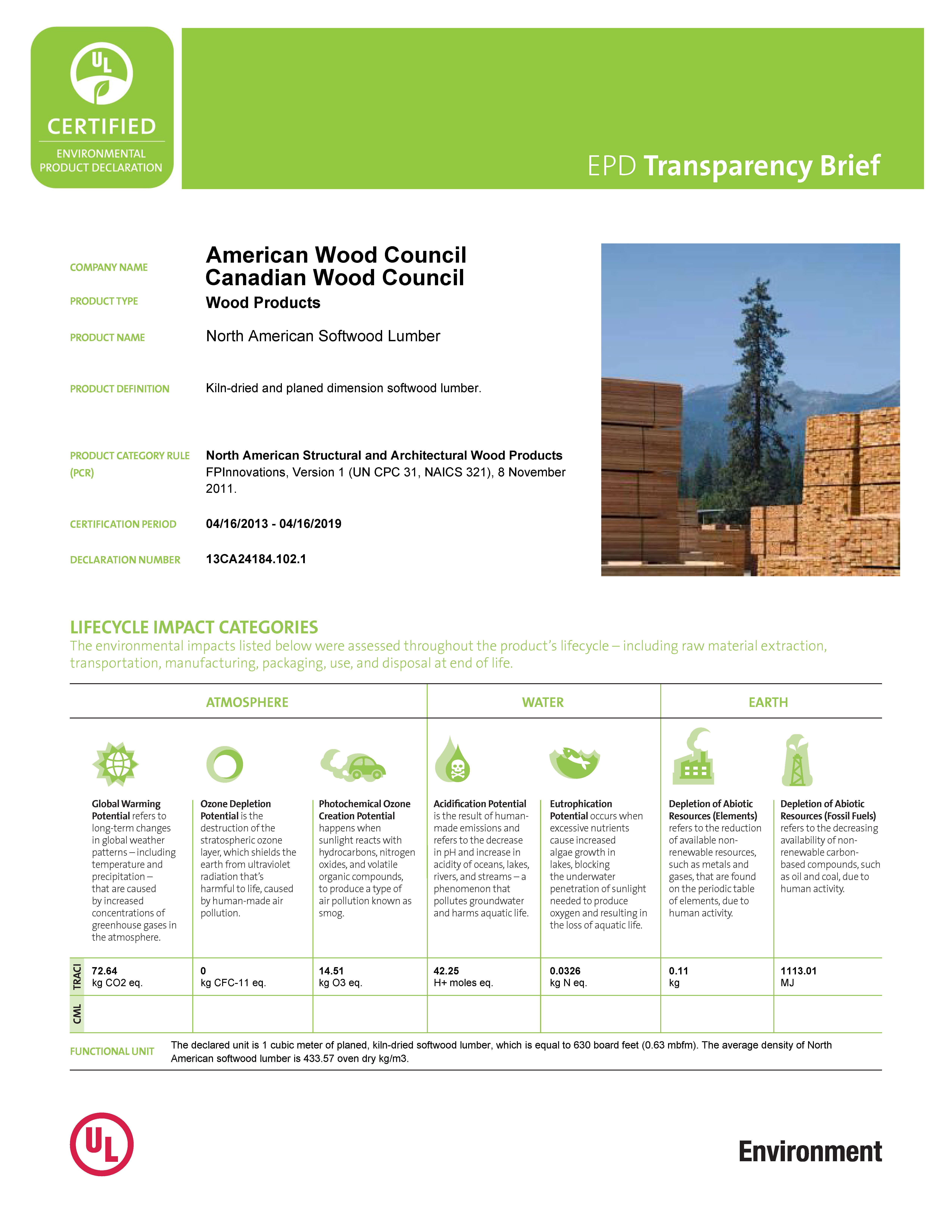

In more detail, EPDs must provide information on the following environmental impacts:

- Global warming potential refers to the long-term changes in global weather patterns—including temperature and precipitation—that are caused by increased concentrations of greenhouse gases in the atmosphere.

- Ozone depletion potential is the destruction of the stratospheric ozone layer, which shields the earth from ultraviolet radiation that’s harmful to life, caused by human-made air pollution.

- Photochemical ozone creation potential happens when sunlight reacts with hydrocarbons, nitrogen oxides and volatile organic compounds to produce a type of air pollution known as smog.

- Acidification potential is the result of human-made emissions and refers to the decrease in pH and increase in acidity of oceans, lakes, rivers and streams—a phenomenon that pollutes groundwater and harms aquatic life.

- Eutrophication potential occurs when excessive nutrients cause increased algae growth in lakes, blocking the underwater penetration of sunlight needed to produce oxygen and resulting in the loss of aquatic life.

Additionally, EPDs can report other important measures, such as:

- Depletion of abiotic resources (elements) refers to the reduction of available non-renewable resources, such as metals and gases, that are found on the periodic table of elements, due to human activity.

- Depletion of abiotic resources (fossil fuels) refers to the decreasing availability of non-renewable carbon-based compounds, such as oil and coal, due to human activity.

On behalf of the wood products industry, AWC provides the building industry’s first third-party verified EPDs and Transparency Briefs that describe the environmental performance of the most common wood products produced in North America. Nine of these EPDs were recently granted a one-year extension by Underwriters Laboratories Environment (ULE), an independent certifier of products and who also serves as the Program Operator for AWC’s EPDs.

EPDs are intended to be open and transparent, outlining where wood products have optimal environmental performance capabilities as well as areas for improvement. This form of data helps to level the playing field for competing building products and mitigate misconceptions about wood that may have existed without technical justification.

EPDs are intended to be open and transparent, outlining where wood products have optimal environmental performance capabilities as well as areas for improvement. This form of data helps to level the playing field for competing building products and mitigate misconceptions about wood that may have existed without technical justification.

Business purchasing decisions will likely require the kind of environmental information provided by EPDs in the future to account for factors such as carbon footprint. By choosing wood, builders can reduce the carbon footprint of materials used during construction, collectively contributing to a reduction in global warming. According to the Intergovernmental Panel on Climate Change, "Wood products can displace more fossil-fuel intensive construction materials such as concrete, steel, aluminum, and plastics, which can result in significant emission reductions."

The North American wood products industry has taken its EPDs one step further by obtaining third-party verification in accordance with international standards (ISO 14025), which establish the principles and specify the procedures for developing environmental declaration programs and environmental declarations.

AWC provides EPDs for the following wood products:

AWC provides EPDs for the following wood products:

- Softwood lumber

- Softwood plywood

- Oriented strand board

- Glued laminated timbers

- Laminated veneer lumber

- Wood I-joists

- Redwood decking

- Medium density fiberboard

- Cellulosic fiberboard

- Laminated strand lumber

All of the EPDs were developed in conjunction with the Canadian Wood Council, with the exception of the Redwood Decking EPD, which was developed with the California Redwood Association.

Moreover, an EPD Transparency Brief summarizes the most critical data presented in an EPD, including product composition, life-cycle environmental impacts, material content, water and energy usage, and other product information, all in a format standardized by ULE. Transparency Briefs are designed to make it easier for users to understand key product details and narrow in on just the environmental data.

Life-cycle assessments have consistently shown that wood products offer significant environmental benefits with a lighter carbon footprint, lower greenhouse gas emissions and energy efficient advantages throughout the life of a structure. For the purpose of EPDs, LCAs are conducted for cradle-to-gate performance, from the extraction of raw materials to the factory “gate” or the point at which the product or material has been manufactured and is ready for shipment. By definition, an EPD for a commodity product like lumber can only be cradle-to-gate because the manufacturer may not be able to characterize how the product is used after it is sold.

Life-cycle assessments have consistently shown that wood products offer significant environmental benefits with a lighter carbon footprint, lower greenhouse gas emissions and energy efficient advantages throughout the life of a structure. For the purpose of EPDs, LCAs are conducted for cradle-to-gate performance, from the extraction of raw materials to the factory “gate” or the point at which the product or material has been manufactured and is ready for shipment. By definition, an EPD for a commodity product like lumber can only be cradle-to-gate because the manufacturer may not be able to characterize how the product is used after it is sold.

Green building codes, standards, rating and certification systems are further driving demand for verified LCA information on products, with notable examples including Leadership in Energy and Environmental Design (LEED), Green Globes, the California Green Building Standards Code (CALGreen), the International Green Construction Code (IgCC) for commercial buildings, and the International Code Council's ICC 700—the National Green Building Standard aimed at residential and multifamily construction. This list will continue to grow in the coming years, but meanwhile EPDs have enabled construction professionals to evaluate and compare products in an informed and timely manner.

All that said, wood is easy to build with, resilient and is the only building material made from renewable resources that sequester carbon. These third-party verified EPDs provide users with a transparent, science-based tool to understand and weigh what environmental factors are important to them when making their product selections. To learn more about EPDs for sustainable wood buildings, visit www.awc.org/sustainability.