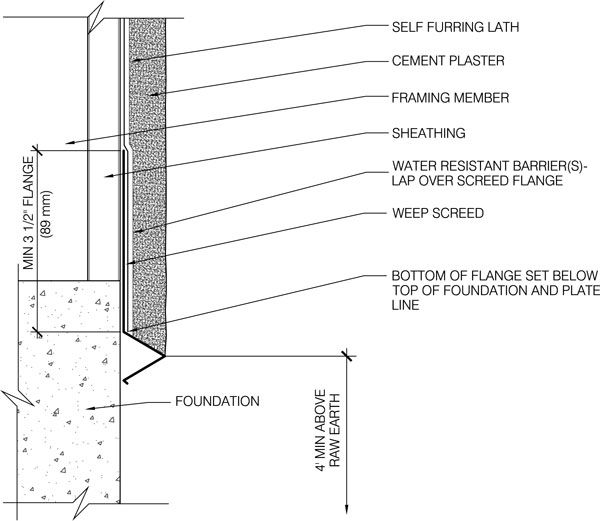

Weep Screed Flashing

Weep screeds are common and code required (IBC Section 2512) for cement plaster over framed walls. Typically they should be set at or below the foundation plate line to allow moisture to exit or “weep” out and to prevent ground moisture from wicking up. The weep screed may be made for galvanized metal, plastics or aluminum. The weep screed may be a V nose (as shown) or a casing bead style with holes for drainage.

The attachment flange should be at least 3 ½ inches in height and the bottom of the attachment flange must be below the plate line. The nose of the weep screed should be 4 inches above earth. The water-resistant barrier should lap over the attachment flange of the weep screed by at least 2 inches. The weep screed can be installed along long runs and overlap each other, or abutted. If they are abutted, the vertical joint between attachment flanges should be covered completely by the water-resistant barrier. Weep screed flashing is not needed on masonry or concrete substrates.

Detail courtesy of Wall and Ceiling Conference