From initial construction to eventual renovation or replacement, every building uses energy, water, and raw materials while generating waste and atmospheric emissions throughout its life cycle. International treaties, governmental and industry regulations, building codes, and third-party certifications have evolved in the past few decades to minimize the negative impacts that buildings impart on the environment. These rising standards cause periodic changes in the materials and methods used by the design and construction industries. Most recently, a trend in climate regulations has focused on lowering the global warming potential (GWP) of substances used in the manufacture of various building components, from insulation products to air conditioning and refrigeration systems.

Background

In the late 1980’s, the Montreal Protocol first limited and then banned the use of substances with measurable ozone depletion potential (ODP). This global effort to reduce emissions of ODP substances required manufacturers of building products in the United States and Canada (and across the globe) to phase out the use of CFCs and HCFCs in various products and replace them with non-OPD alternatives. Manufacturers turned to various technologies during this era and in the building insulation sector, foam insulation manufacturers adopted different technologies to evolve their respective products with varying impacts on the environment.

In one move away from ODP substances, insulation manufacturers that produced extruded polystyrene (XPS) and spray polyurethane foam (SPF) products converted to using hydrofluorocarbons (HFCs) as blowing agents in their manufacturing processes. HFCs provide good insulative value, but have high-global warming potential (GWP). A high-GWP value means the substances trap more heat in the atmosphere and contribute more to global warming than available alternatives.

Conversely, other insulation manufacturers of products like polyisocyanurate (polyiso) and expanded polystyrene (EPS) insulation either transitioned directly to low-GWP solutions (from predecessor substances) or have historically used low-GWP solutions exclusively. For manufacturers that underwent a transition, these low-GWP blowing agent solutions required more comprehensive redesign of product chemistries; however, the low-GWP solutions significantly reduced the environmental impact of the products as compared to alternative blowing agent options like HFCs. Today, polyiso and EPS insulation manufacturers continue to use these trusted, non-ODP, low-GWP blowing agents in the product formulations.

U.S. and Canada: HFC Restrictions

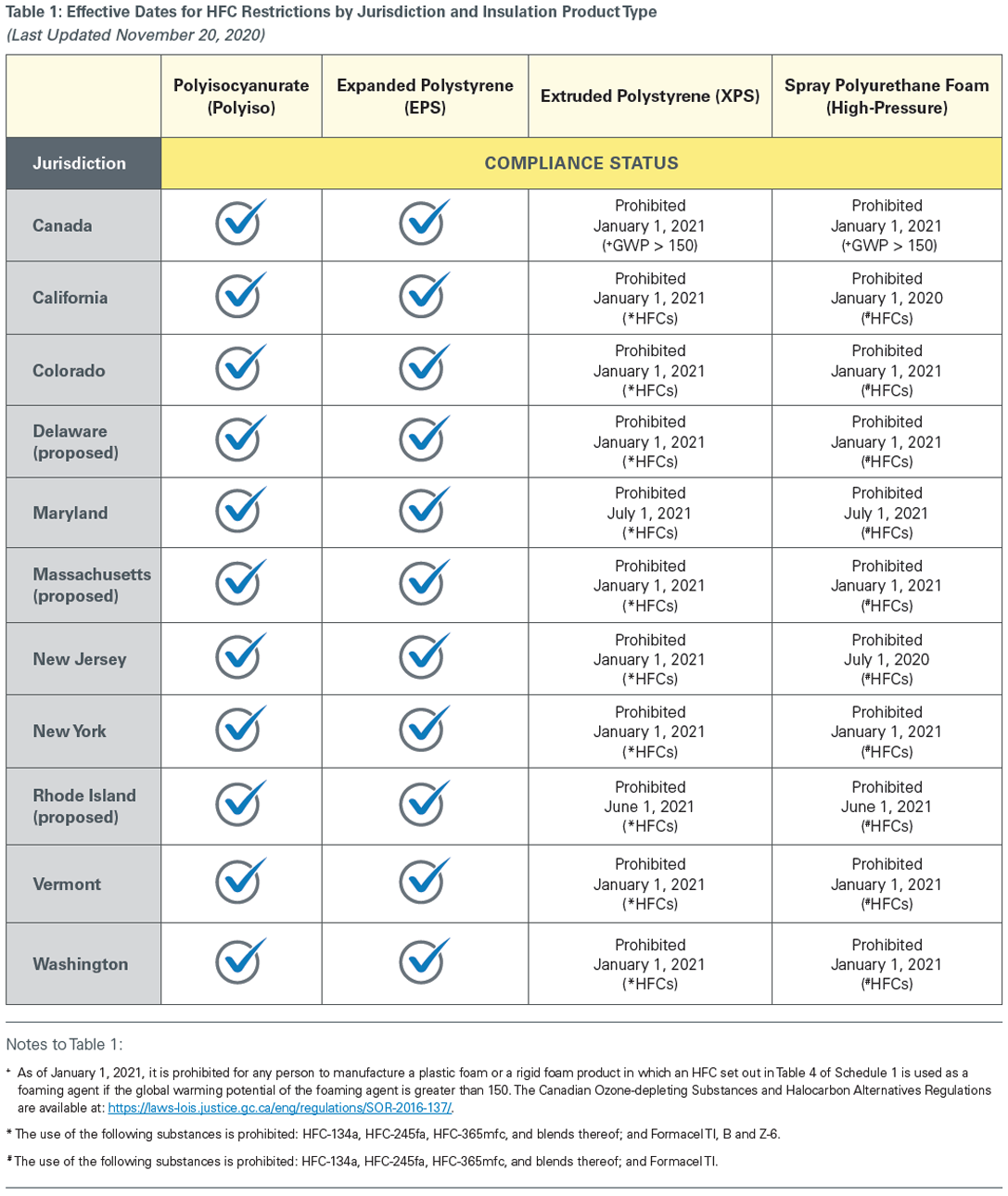

Canada and a growing number of state jurisdictions in the United States have recently adopted—or are in the process of adopting—regulations that prohibit the manufacture and use of common building insulation products produced with high-GWP blowing agents (HFCs). These regulations are intended to meet the obligations of the Kigali Agreement—an international accord under the Montreal Protocol to reduce the consumption and production of HFCs.

As a result of these actions, manufacturers that use HFCs in the production of their products must now develop new, low-GWP formulations in order to meet the regulatory limits.

In the U.S., individual states are leading the transition to the use of low-GWP blowing agents in building products, including insulation. A coalition of 25 state governments have come together to form an organization called the U.S. Climate Alliance to cooperatively address a broad set of climate related issues—including restricting the use of HFCs. The Alliance has developed a model rule to guide the development of HFC restrictions at the state level, which provides a basic framework to help states move quickly to adopt meaningful and practical restrictions on the use of HFCs.

For example, California, New York, New Jersey, Vermont and Washington have enacted legislation or regulations prohibiting the use of HFC substances in building products, such as foam insulation and foam adhesives and sealants. As of October 2020, at least 10 other states are considering legislation or regulations to restrict the use of HFCs.

In Canada, Environment and Climate Change Canada has applied a more uniform approach in enacting nationwide restrictions on the use of HFCs. As of January 1, 2021, no plastic or rigid foam product can use an HFC substance or HFC blend with a GWP greater than 150. The effect of these restrictions is that manufacturers using HFCs will need to reformulate with new, low-GWP technologies or blends.

What Products are Impacted?

Blowing agents are key components in the formulation of certain building products like foam adhesives, one-component foam sealants and foam insulation. Blowing agents imbue the final product with specific physical properties such as thermal performance and/or are necessary to facilitate the manufacturing or application process for the product. A good example of a product that relies on blowing agent technologies is closed-cell foam insulation. In closed-cell insulation products, certain quantities of the blowing agents used to create the foam during manufacture are retained within the cell structure contributing to the product’s thermal performance.

Insulation products differ in their manufacturing processes and in the types of specific blowing agents used. As detailed above, products like polyiso and EPS insulation already comply with the new low-GWP requirements based on proven blowing agent formulations, while other products like XPS and SPF insulation may require new formulations. A summary of how recent climate regulations impact the most common types of rigid foam insulation products is provided here:

Products not impacted (due to existing low-GWP formulations):

- Polyisocyanurate (polyiso) insulation is manufactured with pentane (or pentane blends) as the blowing agent. Pentane is a non-ODP, low-GWP substance. Therefore, polyiso insulation is not impacted by the climate regulations, and designers and contractors should not expect to see changes in polyiso products as a result of any HFC restrictions.

- Expanded polystyrene (EPS) insulation has always used non-ODP, low-GWP pentane as the blowing agent. The pentane is rapidly exchanged with air during manufacture, resulting in a product with stable thermal performance that designers and specifiers can rely upon.

Products impacted (due to the historic use of HFCs in product formulations):

- Spray polyurethane foam (SPF) insulation is traditionally manufactured with HFC blends. Most SPF manufacturers have introduced new, low-GWP formulations using new technologies like hydrofluoroolefins (HFOs) in the past several years. Builders working in states that prohibit the use of HFC-based products will need to be familiar with the available HFO-based SPF products. Similarly, low-rise foam adhesives and other foam products and sealants will be subject to the same HFC restrictions as SPF insulation.

- Extruded polystyrene (XPS) insulation is traditionally manufactured with HFCs. Certain manufacturers may offer low-GWP solutions that are compliant with new restrictions; other manufacturers offer “reduced-GWP” solutions that still contain HFC blends with GWP values as high as 750. These reduced-GWP solutions may not be permitted in jurisdictions with effective HFC restrictions. Projects that specify XPS insulation and are located within a jurisdiction that prohibits the use of HFC-based foam products will need to consult with product manufacturers to discuss the availability of compliant, low-GWP options.

The chart below outlines the compliance status of these common rigid foam insulation products by country or state jurisdiction. (Note: The chart includes both effective and proposed GWP restrictions.)

Steps for Compliance with HFC Restrictions

Learning to identify products that utilize low-GWP technologies can help designers and contractors ensure that they are specifying and installing compliant building products in states and jurisdictions with active restrictions. A familiarity with the product offerings and applicable restrictions can save time and frustration on the jobsite. Some key questions to ask include:

- Where is the product being installed and does that jurisdiction have HFC restrictions?

- Does the specified product contain HFCs?

- If yes, when was the product manufactured?

Once these basics are established, designers and contractors can move forward with confidence knowing that the project complies with the regulations. To better facilitate compliance, here are a couple of things to keep in mind:

Choose Low-GWP Products

If your project goals include ease of compliance with the new restrictions and selecting products with minimal environmental impacts, it may be easiest to select products that comply with the restrictions based on existing technologies. Building products that meet the new standards are widely available and include polyiso and EPS insulation. Products that have traditionally used low-GWP blowing agents have a track record of meeting the material specifications for a wide-variety of projects.

Other product manufacturers are still transitioning their product portfolios to low-GWP formulations. For product categories in transition like SPF and XPS insulation, designers and contractors should learn how to differentiate between low-GWP and HFC-based formulations. Products may be branded as “low-GWP” and some products will carry labels stating that the product is compliant with HFC restrictions. However, it is important to know the difference between products advertised as “low-GWP” and “reduced-GWP;” reduced-GWP products may still contain HFC blends with GWP values as high as 750 and may not comply with active regulations.

Identify Date of Manufacture

Thus far, each jurisdiction with effective restrictions has included “sell through” provisions that allow product manufactured prior to the effective date of the restrictions to remain in commerce until they are used or installed. Designers and contractors may still have products that use an HFC-based formulation in their supply chain. Designers and contractors that are planning to specify and install these products in states with active restrictions should determine when the products were manufactured in order to ensure they can be used and installed.

Take Care Not to “Import” Non-compliant Product

Designers and contractors should closely track HFC restrictions in neighboring states. Those conducting business in multiple states should ensure they do not “import” non-compliant products that contain HFCs into states where their import and use is restricted. Remember, nearly 15 states and Canada have either effective restrictions on high-GWP products or are considering adopting proposed restrictions.

As global efforts to abate climate change and accelerate the adoption of more environmentally friendly materials increase, the regulatory landscape for designers, builders and contractors is changing quickly. While it may seem daunting to keep up with all of the new targets and guidelines, resources within the manufacturing industry and from regulatory organizations are available to help.

References

1. Information on the U.S. Climate Alliance is available at http://www.usclimatealliance.org/.

2. More information on polyisocyanurate insulation products is available at https://www.polyiso.org/page/Low-GWPBlowingAgentSolution.