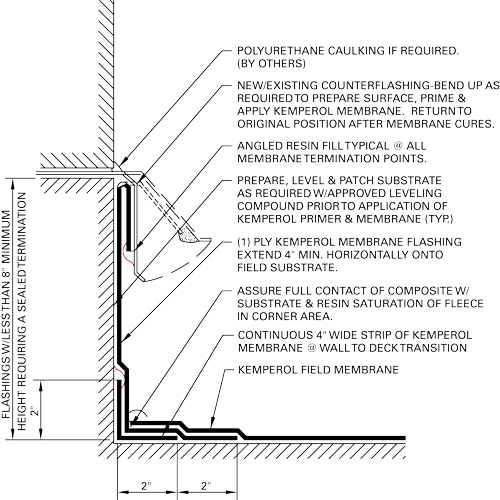

Detail courtesy of Kemper System.

Flashing terminations may be mechanically secured using metal termination bars or by stripping off into a recessed form of a reglet design. However, it is a best practice to follow termination designs that are in accordance with the material manufacturer’s recommendations.

A double-bladed saw cut or formed-in-place reglets can be good solutions for flashing and wall terminations because each can be easily corrected or re-worked. Double-bladed saw-cut reglets, termination bars and possibly through-wall, under-cap solutions or through-wall, behind-wall fascia are normally the only alternatives possible in retrofit and remedial work.

In all cases, the membrane flashing should be raised well above the usual 6-inch minimum or the expected “water line” of the finished wear surfaces. A cast-in-place curb will form a good protective barrier against damage during construction and after it is complete.

Detail courtesy of Kemper System.