With the snow finally melting off many roofs and spring ready to pop, here are key considerations about the storage and handling of polyiso roof insulation on a jobsite.

Storage

Polyiso insulation is typically shipped protected by a plastic wrap, plastic bag or both. This factory packaging is intended for handling the polyiso in the manufacturing plant and during transit; it should not be relied upon as protection at jobsites or other outdoor storage locations unless specified otherwise by the manufacturer.

Material delivery should be carefully coordinated with the roof application schedule to minimize outdoor storage. When short-term outdoor storage is necessary, whether at grade or on the roof deck, the following precautions should be observed:

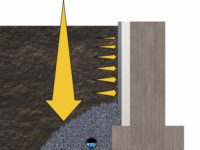

- Bundles should be stored flat above the ground utilizing included feet or on raised pallets. If possible, the bundles should be placed on a finished surface such as gravel, pavement, or concrete rather than on dirt or grass.

- Unless specified otherwise by the manufacturer, cover the package and pallet with a waterproof cover, and secure to prevent wind displacement.

Note: Polyiso insulation is fully cured and fit for installation upon delivery. No additional storage time is required.

Handling

Exercise care during handling of polyiso insulation to prevent breaking or crushing of the square edges and surfaces. Remove the polyiso bundles from trucks with proper equipment. Other means of mishandling, such as pushing pallets off the edge of the truck or “rolling” the pallet across the roof deck, must be avoided.

Product Application

Polyiso should always be installed on dry, clean roof decks in dry conditions. Follow the manufacturer’s recommendations regarding product application to ensure performance to the intended design life of the roofing system. Apply only as much polyiso roof insulation as can be covered by completed roofing the same day.

Construction Traffic

Avoid excessive traffic during roof construction of or on a completed roof surface. Although polyiso has been designed to withstand limited foot traffic, protection from damage by construction traffic and/or abuse is extremely important. Roof surface protection such as plywood should be used in areas where storage and staging are planned and heavy or repeated traffic is anticipated during or after installation.

Some designers and membrane manufacturers specify the use of coverboards as a means of protecting the insulation. If specified, installers should ensure that the coverboard used is compatible with all components of the roofing system, is acceptable to the membrane manufacturer, and meets specified fire, wind and code requirements.

Polyiso roof insulation, like other roofing materials, requires a proper understanding of storage, handling and application to result in a properly constructed roof system. You can find additional technical information about polyiso roof and wall insulation at polyiso.org.