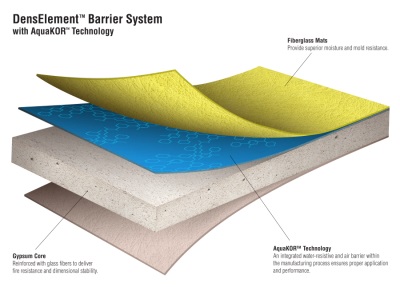

Georgia-Pacific introduced patent-pending DensElement Barrier System with AquaKOR Technology, a new water-resistive and air barrier (WRB-AB) system solution for the installation of exterior walls in commercial construction.

“Thirty years ago, Georgia-Pacific led the evolution of exterior wall construction with the introduction of our Dens brand portfolio of fiberglass mat gypsum products,” said Brent Paugh, president for Georgia-Pacific Gypsum. “Today, we remain focused on customer needs and we’re proud to announce the launch of our new DensElement Barrier System. With skilled labor being difficult to find, this new system solution significantly reduces the amount of time it takes to install exterior walls and the associated water and air barrier, ultimately saving time and labor.”

The all-in-one sheathing system integrates a WRB-AB directly into the gypsum sheathing panel’s core to eliminate an entire step in the typical weatherization process for commercial buildings. To tightly seal the system, Georgia-Pacific collaborated with PROSOCO Inc. A quick application of PROSOCO’s R-Guard FastFlash liquid flashing fills and seals all joints, fasteners and other penetrations to finish the system with no need to fully cover or coat the entire wall.

The all-in-one sheathing system integrates a WRB-AB directly into the gypsum sheathing panel’s core to eliminate an entire step in the typical weatherization process for commercial buildings. To tightly seal the system, Georgia-Pacific collaborated with PROSOCO Inc. A quick application of PROSOCO’s R-Guard FastFlash liquid flashing fills and seals all joints, fasteners and other penetrations to finish the system with no need to fully cover or coat the entire wall.

“Just like Georgia-Pacific pioneered the sheathing market 30 years ago with DensGlass GOLD Sheathing, PROSOCO was a pioneer of silyl-terminated polymer (STP) technology more than a decade ago,” said Dave Pennington, building envelope group manager for PROSOCO’s R-Guard products.

“R-Guard FastFlash liquid flashing is the only fluid-applied flashing product on the market today with 10-plus years of proven performance. So it’s a perfect fit for PROSOCO to partner with another leader in the industry that makes time-tested and field-proven products.”

To validate the labor benefits of the system, Home Innovation Research Labs, a third-party building science research expert, conducted a time-motion study comparing the DensElement Barrier System against two typical WRB-AB systems. The DensElement Barrier System demonstrated a 40 percent reduction in installed man-hours when compared to the fluid-applied membrane in the study; and a 25 percent reduction in installed man-hours when compared to the building wrap in the study. Although actual results may vary depending on the system, the building, the installation methods and other factors, these results illustrate the significant time savings potential for commercial building envelope projects.

“Products on the market today that cover the entire face of the sheathing, like building wrap, fluid-applied WRBs and peel-and-stick membranes, are time-consuming and labor-intensive to install,” said Jason Peace, director of product management and marketing for Georgia-Pacific Gypsum. “In some cases, they prevent moisture from escaping the wall cavity, causing harmful mold, mildew or deterioration.”

According to the American Institute of Architects, up to 80-percent of building envelope failures are moisture-related, with water infiltration being the main culprit. The high vapor permeability of the DensElement Barrier System helps mitigate moisture issues in the wall cavity – walls are able to dry out if water is introduced, rather than trapping it inside the wall cavity.

The DensElement Barrier System offers architects, specifiers and contractors a performance-tested solution for building envelope construction. In rigorous lab testing and several southeast job sites, the system has proven time savings, reduced skilled labor needs, and saved bottom-line costs.

For more information, visit www.DensElement.com.