If you haven’t seen the new energy codes enforced yet in your area, you probably will in the near future. Though many different methods of continuously insulating a structure have been employed for decades (EIFS for example), the majority of commercial contractors have limited experience in how to properly install and integrate CI into the building envelope. I have spoken with many contractors about their apprehension or fear of installing continuous insulation simply from a lack of understanding of how the various components are to be installed and how they will work together. But like with any challenge comes opportunities.

been employed for decades (EIFS for example), the majority of commercial contractors have limited experience in how to properly install and integrate CI into the building envelope. I have spoken with many contractors about their apprehension or fear of installing continuous insulation simply from a lack of understanding of how the various components are to be installed and how they will work together. But like with any challenge comes opportunities.

Whether you are a seasoned insulation contractor or just “dipping your toe into the water” to see if you want to include the CI into your next bid-scope you need to focus on the details.

An Overview of CI

As defined by Dow Building Solutions, “continuous insulation is the only way to block thermal bridging. Wrapping the exterior wall in a continuous layer of rigid foam protects the cavity and the stud, providing high R-value in several ways:

- “Continuous insulation minimizes the temperature differential between the stud cavity and the stud, reducing condensation and corrosion potential for steel components.”

- “Continuous insulation reduces heat loss due to thermal bridging increasing the effective R-value of the wall system.”

- “With continuous insulation, the dew point can be moved from inside the stud cavity into the CI insulation layer, minimizing the potential for mold and mildew accumulation inside the wall.”

- “When combined with a drainage plane and moisture barrier, continuous insulation provides better protection against water intrusion, reduces material degradation and extends the service life of the home or building.”

Not all rigid or continuous insulation is created equal nor is there a “one size fits all” solution. Rather, the architect or building designer has to consider thermal performance, vapor permeance, fire resistance, moisture absorption characteristics, and cladding attachment over the insulation, etc. As insulation manufacturers continue to work with other accessory and component manufacturers to “systemize and accessorize” insulated wall solutions, it becomes even more important to focus on these details.

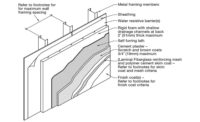

The Components

Critical components include insulation fastening systems, veneer anchoring systems, flashing/tape/WRBs, and moisture management systems, etc. According to Herbert Slone, registered architect, and director of commercial building systems at Owens Corning, “We’re working to make the architect’s and contractor’s job easier by sorting out options and packaging specific system details. We’re working to put together complete ‘system’ offerings, whether the components are owned or partnered. We’re bringing systems together that manage the overwhelming array of options while maximizing and documenting performance. ‘Diversify, accessorize, systemize.’ That is our driving strategy as we work to bring together all of the components in high performance commercial wall systems.”

Testing

Various standardized tests have been developed to ensure that these components work together to prevent moisture and air leakage as well as fire protection. Some of the critical tests include:

- ASTM E2357 is an air leakage test with two separate 8-feet-by-8-feet wall assembly panels—one opaque wall and the other with multiple common penetrations including pipes, windows, electrical boxes, fasteners, veneer anchors, etc. As stated by Laverne Dalgleish, executive director of the Air Barrier Association of America, “Air barrier assembly testing in accordance with ASTM E2357 has become a critical requirement in the air barrier industry. The ASTM E2357 test tells the design professional the materials, components and accessories are actually going to work together and stay sealed during the operation of the building.” The ASTM E2357 test verifies the performance and reliability of the air barrier assembly.

- ASTM E331 is a water penetration test with an 8-feet-by-8-feet wall assembly panel (including necessary building components such as tape, WRBs, self-sealing fasteners, etc.) This test method determines the resistance of walls to water penetration as water is applied to the outside surface with higher air pressure than on the inside face of the building envelope (lower air pressure attempts to draw moisture through the envelope.)

- NFPA 285 is a wall assembly fire test which evaluates fire propagation characteristics of exterior non-load bearing wall assemblies containing combustible components.

The Importance of Testing

Why are these tests important? The answer is in the details. The building envelope is a system made up of individual components that must all perform together to ensure long term operation of the building. When bidding, designing or supplying materials for a building with continuous insulation, you need to use the specified accessories including fasteners, tape, drainage protection, cladding attachment system, veneer anchors, etc.

Important things to consider include: Is the CI being applied over gypsum sheathing and a weather resistant barrier or directly to the steel studs or concrete? Which washers and screws and how many fasteners are required per board for proper attachment? Do the joints of the board and the fasteners require tape for weatherization? What is the specified method to flash door and window penetrations, pipes, outlets, etc.? All of these are critical installation details that should have been addressed and tested as an assembled system. Next time you are asked to “value engineer” something as important as the building envelope keep in mind that until each component has been fully system tested in a wall assembly, there is no such thing as “or equal.”

Continuous insulation is a good thing for our society—simply put, it is a smarter way to insulate and construct our buildings. It is a good thing for our walls and ceilings industry as it has and will continue to develop even greater energy efficient building solutions. It can be a good thing for your business and bottom line as it provides an opportunity to increase your bid-scope and role in constructing the building envelope. You can do this—just make sure you focus on the details.