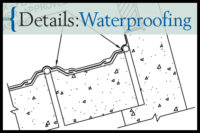

Detail courtesy of Alvaro Mejia, IRT Inc.

This detail provides proper application method of sheet or reinforced membrane waterproofing systems. The vertical footing wall/slab intersection is a vulnerable location and it requires additional protection to eliminate moisture infiltration. The detail applies to these locations.

Materials

• Flashing material: Reinforced flashing membrane required by the waterproofing system manufacturer.

• Adhesive/bitumen: Adhesive or hot bitumen as required by the waterproofing system manufacturer.

• Tape: Butyl sealant tape.

• Water stop: Approved chemical material.

Execution

At the footing wall/slab intersection:

1. Apply a chemical water stop to the exterior of the reinforcing steel at the cold joint of the footing wall/ slab intersection.

2. Coat corner and both sides 12 inches out and to the height of the vertical substrate.

3. Embed 7/8-inch-by-7/8-inch butyl sealant tape to the height of the vertical substrate and press it tightly into the corner.

4. Pre-cut two 12-inch widths of waterproofing sheet to the height of the vertical substrate.

5. Install the first ply 9 inches to the first side and 3 inches to the second side. Reverse-install the second ply with 3 inches to the first side and 9 inches to the second side.

6. Embed the sheets in the manufacturer’s approved adhesive or bitumen material in application rate in accordance with the manufacturer’s latest printed specifications. Apply waterproofing system over the completed footing wall/slab intersection detail. The waterproofing shall extend a minimum of 3 inches out onto the footing. 7. Apply a protection board or a 6-mil polyethylene film over the waterproofing in accordance with the manufacturer’s specifications.

8. Extruded polystyrene insulation is applied over the protection layer prior to backfill. If the waterproofing manufacturer requires a concrete cant, then the EPS insulation should be angled to conform to the cant.