In the realm of sustainable construction, the term "embodied carbon" has been gaining traction as a critical factor in assessing the environmental impact of buildings. While much attention has historically been focused on operational carbon emissions generated during a building's lifecycle, the significance of embodied carbon cannot be overstated.

According to the Carbon Leadership Forum, embodied carbon refers to the total global greenhouse gas emissions (GHG) associated with the extraction, manufacturing, transportation, and assembly of building materials. It encompasses the carbon dioxide (CO2) emissions released throughout the entire lifecycle of a building, from the initial stages of material production to the eventual demolition or renovation.

State of Embodied Carbon: A Shifting Policy Landscape

In recent years, there has been a paradigm shift in the building industry towards recognizing the importance of embodied carbon. With increasing awareness of climate change and the urgent need to curb carbon emissions, stakeholders are reevaluating traditional approaches to construction and exploring innovative strategies to minimize environmental impact.

According to the New Building Institute, the building and construction industry is responsible for 39 percent of GHG emissions. And “of these emissions, one-third comes directly from the creation of construction products and construction activities.”

The industry is addressing the significant influence of the building industry on GHG emissions in a number of ways. Policy is a key component in the carbon equation, with some cities and states adopting policies around embodied carbon.

In 2023, California became the first state to approve what they call a “whole-building” embodied carbon policy in its state building code. Additionally, national green building codes are being adapted to address embodied carbon emissions. As the New Building Institute put it, “Following the approval of two new code amendments by the ASHRAE 189.1 Committee, a mandatory low-carbon building product procurement requirement is poised to become part of the International Green Construction Code (IgCC) / ASHRAE 189.1.” The IgCC makes specific requirements to promote safe, sustainable construction, governing the environmental impact of commercial buildings.

Nationally, the government is working to drive progress as well. In Sep. 2022, the federal government launched the Buy Clean Initiative to “spur the development of low-carbon construction materials made in America.” In addition to prioritizing the government’s purchase of products like steel and concrete that have lower levels of emissions, the government is also working to expand lower-carbon construction materials in federally-funded projects to drive progress. The Buy Clean Initiative is also working to bring state governments into the initiative by providing incentives to develop and expand “clean” manufacturing and low carbon materials for buildings and infrastructure that support government. Buy Clean is also driving manufacturers throughout the country to increase data transparency through reporting efforts, so that GHG emissions are a part of the material selection process for buildings.

Reducing the Footprint: Industry Initiatives

Efforts to reduce embodied carbon are multifaceted and involve various stakeholders across the supply chain. In addition to policymakers becoming more aware of and invested in reducing embodied carbon emissions, manufacturers, architects, contractors, engineers, and even technology firms are now collaborating to integrate sustainable practices into building, design and construction processes.

Material Selection

The Buy Clean Initiative is helping drive transparency around GHG emissions in the material selection process. Upfront material selection can have the biggest long-term impact on the embodied carbon of a building.

Take steel, for example. According to the USGBC, “The International Energy Agency estimates that the manufacturing of iron and steel is responsible for approximately 7 percent of global CO2 emissions. As steel melts at a temperature between 2,500°F and 2,800°F, depending on its makeup, an incredible amount of energy is required in its creation before this material ever makes it to a job site.” Because of this intense process, prioritizing recycled steel in the material selection for buildings has the potential to significantly reduce embodied carbon.

Aluminum is another great example. Known as one of the most environmentally friendly metals, aluminum is 100 percent recyclable, easy to handle and light to transport, reducing overall transportation costs. However, because of its energy-intensive production processes, aluminum producers are adopting “green aluminum,” which leverages even more environmentally friendly production processes. According to Harbor Aluminum, this includes “shifting toward the use of renewable energy, and investing in new green smelting technologies or even studying carbon capture and storage solutions to accelerate their decarbonization efforts.” As a result, the adoption of this “green aluminum” is in high demand.

Additionally, carbon-storing materials like wood, hemp, straw bamboo, and algae, and low-impact concrete alternatives, like green concrete developed by McHugh Concrete, can make an incredible impact on reduction of GHG on the industry.

Environmental Product Declarations, or EPDs, are a crucial piece of the puzzle in the material selection process, and help encourage manufacturer transparency. An EPD demonstrates a manufacturer’s commitment to sustainability and to the environment by providing objective data that communicates what a product is made of and how it impacts the environment.

A few noteworthy projects have publicly discussed the selection of lower carbon materials and their impact on building performance. Amazon’s second headquarters in Arlington, Va. used a combination of sustainable mass timber and low-carbon concrete in its development, and predicted this would have a 15 percent reduction in the carbon footprint of the building.

Another project, Microsoft’s data center site in Quincy, Washington replaced concrete with a limestone material “derived from microalgae” with the goal of cutting carbon emissions from concrete in half.

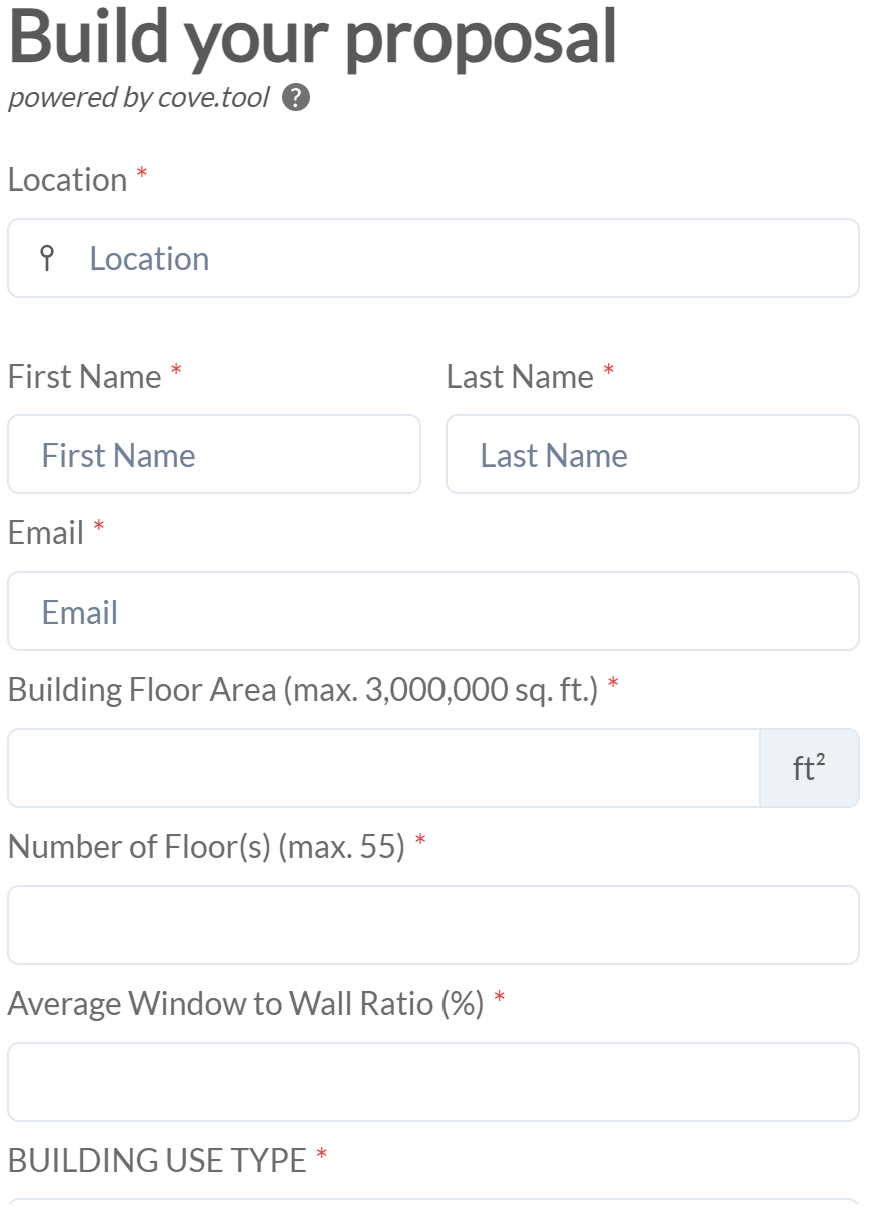

In order to help manufacturers and architects in the product selection process, many software companies are providing innovative solutions. A recent example is the software company cove.tool. In 2023, the company launched revgen.tool as a design assist solution to empower building product manufacturers with critical data for architect’s product decisions. Tools like revgen.tool help architects run advanced energy and carbon simulations to best choose high performing building products. Building facade manufacturer, YKK AP America, was the first manufacturer to partner with cove.tool to provide architects with real-time, project-specific performance analysis, allowing them to select products that best align with their carbon goals.

The figure above shows the Sustainable Design Tool now offered by cove.tool and YKK AP America, which better helps architects to choose high-performing building facade products for their projects.

Optimized Design

While material selection has a lasting impact on the embodied carbon of a building over the long term, optimizing design has the biggest short-term impact. Designing in a way that minimizes material use, like in modular construction, can drastically reduce embodied carbon.

Modular construction involves constructing a building in a factory-controlled environment, and then shipping it to a jobsite for installation. A factory-controlled process typically generates less waste, given that materials can be recycled, inventory can be controlled, and building materials can be protected - without environmental disturbances.

Adaptive reuse is another strategy for optimizing design. Adaptive reuse takes an existing building and uses it for another purpose other than the one for which it was initially designed. Data continues to come to the forefront, showing the impressive carbon savings on adaptive reuse projects. According to environmental design consultants, Atelier Ten, an adaptive reuse project of a vacant campus laboratory at California State University Los Angeles into the university’s new administration building reduced “greenhouse gasses by 78 percent compared to building a new building.” The project also attained LEED Gold certification as a result.

The Troubadour is an adaptive reuse project in the heart of New Orleans. Formerly a 17-story office building, The Troubadour is now a 184-room luxury boutique hotel. It was part of the former Rault Center which was the site of a deadly fire in 1972. The Troubadour was renovated and reopened in Dec. 2016. Photo courtesy of YKK AP America.

Supply Chain Optimization

Streamlining supply chains, sourcing materials locally to reduce transportation emissions, and implementing circular economy principles to promote material reuse and recycling are effective ways to mitigate embodied carbon.

Local Sourcing

Whenever feasible, source materials and components locally to reduce transportation emissions. This can also support local economies and reduce reliance on long-distance shipping.

Efficient Transportation

Optimize transportation routes to minimize distance traveled and reduce emissions. This may involve consolidating shipments, using more fuel-efficient vehicles, and exploring alternative transportation modes such as rail or sea freight when appropriate.

Inventory Management

Implement just-in-time inventory practices to reduce excess inventory and associated carbon emissions from storage and transportation. This involves closely coordinating with suppliers and customers to ensure timely deliveries without overstocking.

Packaging Optimization

Use eco-friendly packaging materials and design packaging to minimize size and weight, thus reducing transportation emissions. Reusable or recyclable packaging options can also help lower the overall carbon footprint.

The Pythian Apartments building in downtown New Orleans was a $44 million renovation completed in June 2017. The historic nine-story building was originally built in 1908 by S.W.Green, the leader of the Grand Lodge Colored Knights, an African American fraternal organization. It once served as a hub for commercial life. The building is now home to 69 apartments that target middle-income workers to provide affordable housing in a desirable downtown neighborhood. Photo courtesy of YKK AP America.

Life Cycle Assessment Tools

Utilizing advanced lifecycle assessment tools and software enables stakeholders to quantify and optimize embodied carbon throughout the design and construction phases.

Life Cycle Assessment, or LCA, assesses the total carbon footprint of a product, whereas Whole Building Life Cycle Assessment, assesses the total carbon footprint of a building. According to the U.S. General Services Administration, “a complete whole building LCA includes all materials in the building but, for simplification, the LCA is often limited to only the materials found in the largest quantities or with the most impact. For a whole building LCA, the functional unit might be ‘the entire building from design to demolition for a 50-year service life,’ or it might be computed on a per-square-foot basis and limited to one life cycle stage (e.g., construction).”

The U.S. General Services Administration recommends the Embodied Carbon in Construction Calculator (EC3). This is an “open-access tool that allows benchmarking, assessment, and reductions in embodied carbon, focused on the upfront supply chain emissions of construction materials.”

Building a Sustainable Future

The benefits of reducing embodied carbon extend far beyond environmental preservation. By adopting sustainable practices, the building industry can drive innovation, enhance resilience, and create healthier, more livable spaces for occupants. Additionally, minimizing embodied carbon can lead to long-term cost savings, improved market competitiveness, and enhanced reputation for stakeholders committed to sustainability.

As the building facades industry continues to evolve, stakeholders must prioritize efforts to reduce embodied carbon through innovative design, material selection, and supply chain optimization. By embracing sustainable practices and leveraging available tools and resources, we can collectively pave the way towards a more resilient, resource-efficient built environment for future generations.