As a leading manufacturer of modified bituminous membranes for more than two decades, Tarco now makes a superior membrane for below-grade waterproofing applications.

Building on its expertise in mod-bit chemistry and its experience with product development as well as its manufacturing know-how, Tarco has created a below grade waterproofing membrane like no other.

“Our goal is to create a product equal to or better than any product in the market today," says David Snowden III, President of Tarco. “We have reached that goal with the BG700, a waterproofing membrane that is in a class of its own.”

Figure 1 — Tarco LeakBarrier BG700 Self-Adhering Waterproofing Membrane |

As Good as it Gets: Two Layers of Protection

BG700 has a nominal thickness of 60 mils. That’s 1.5 mm in the metric system. This nominal thickness includes TWO layers of waterproofing protection: (1) a SBS-modified bituminous layer, and (2) a high-strength, cross-laminated, polyethylene facer.

The facer has exceptional tear resistance and waterproofing characteristics, while the mod bit layer meets the demands of a waterproofing membrane. The specially formulated rubberized asphalt compound yields a pliable sheet that self-seals around fasteners and will not crack or dry. This highly durable material can be used in a variety of applications. It adheres well to a wide range of substrates such as concrete, plywood, OSB, metal, wood, vinyl, masonry, and certain rigid insulations, insulated concrete forms (ICF) etc.

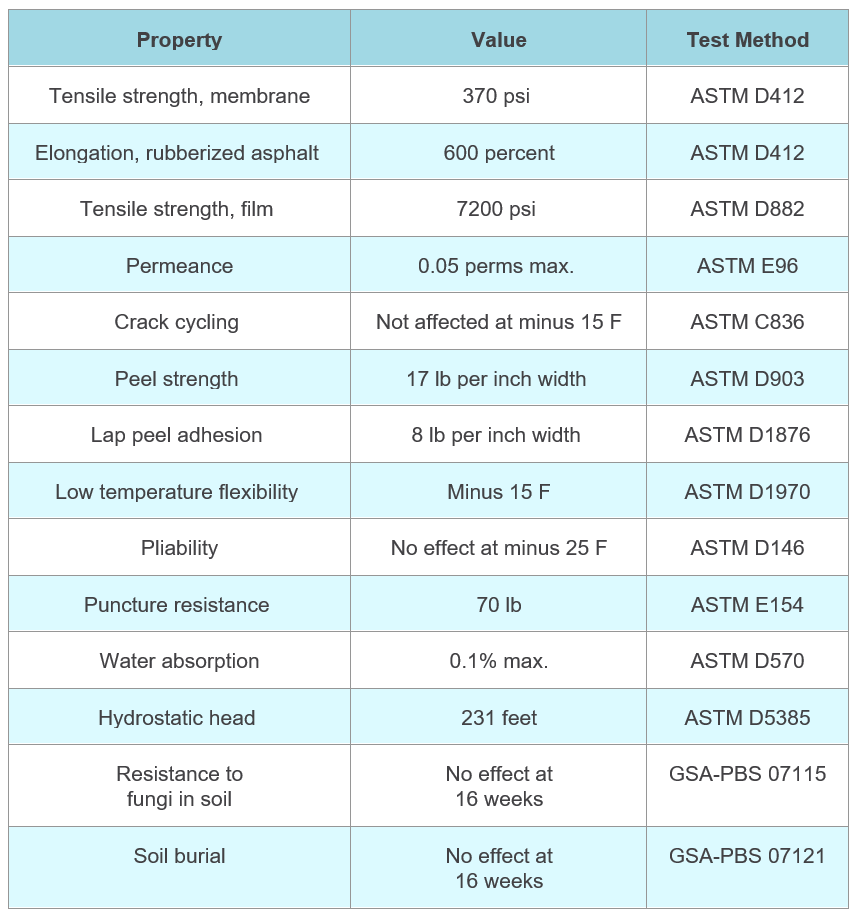

The two layers – that is, the SBS compound plus the polyethylene facer – allow BG700 to equal or surpass competitive membranes in this product category. Standardized tests demonstrate equivalent or superior elongation, crack cycling, tensile strength, peel strength, lap adhesion and puncture resistance. “The waterproofing protection, strength and durability offered by BG700 is as good as it gets,” says Josh Bailey, Business Manager, Building Envelopes Products for Tarco.

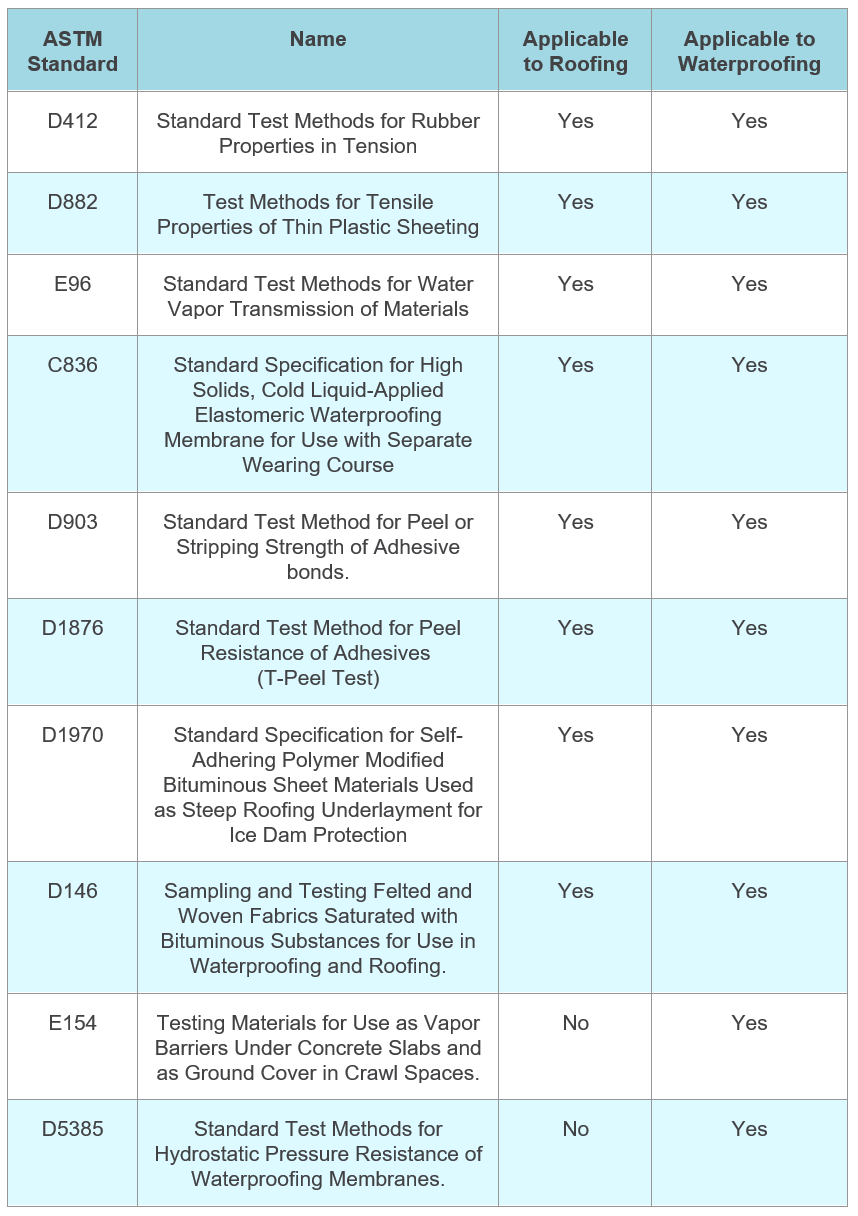

See Table 1 below or visit www.tarcoroofing.com for more information on ASTM standards applicable to roofing and waterproofing. Besides the two layers of waterproofing, BG700 has a removable silicone treated release line on the bottom adhesive side.Table 1 — ASTM Standards Applicable to Roofing and Waterproofing.

Not Only Below Grade

The name BG700 suggests that this extraordinary membrane is suitable for “below grade” waterproofing applications and that is certainly true. However, it is also suitable for countless other waterproofing applications such as the following:

- Under siding, exterior plaster or wall flashing.

- Vertical and horizontal waterproofing of foundation walls, tunnels, and earth shelters.

- Plaza decks, balconies, terraces, and planters.

- Wherever there is a need to resist hydrostatic pressure.

- Strips can be used to patch cracks and repair leaks.

- Interior applications in “wet areas” (such as utility rooms, bathrooms, and kitchens).

Peel-and-Stick Is the Way to Go

A discussion of waterproofing membranes is incomplete without mention of labor savings. When Tarco introduced its LeakBarrier line of premium underlayments in the early 2000’s, one of the main selling points was ease-of-installation, which resulted in labor cost savings. The fact of the matter is that the peel-and-stick characteristics of the waterproofing membrane could well be the unique feature from the point of view of the contractor.

However, not all peel-and-sticks are alike. There is variation from one manufacturer to another. Contractors typically want to try several types of waterproofing membranes until they find one with just the right amount of adhesion. Ensuring the right amount of tackiness, whether on first contact or during repositioning, will be important to your customers. There could be instances where adhesion varies due to ambient temperatures and surface temperatures causing the membrane of some products to improperly adhere. Poor adhesion could result in the use of fasteners, which could in turn increase labor and material costs.

A major advantage of using a self-adhering waterproof membrane has to do with labor savings and ease of application. Depending on the type and size of the application, the use of a peel-and-stick waterproofing membrane could result in considerable labor savings compared to other methods of waterproofing. A peel-and-stick product from Tarco is engineered to provide the exact balance between ease of application and product performance.

Self-adhering modified bitumen membranes take the guesswork out of waterproofing applications. The BG700 membrane sticks to a wide variety of substrates. The peel strength is tested according to ASTM D903 and the lap peel adhesion is tested according to ASTM D1876. Typical values are listed in Table 2. These values can be compared by design professionals against other products and help them identify the right product for the job.Table 2 — Physical Properties as Measured on

Mod Bit Chemistry “Know How” Results in a Winning Formula

Modified bitumen membranes can be used in exterior wall assemblies, below grade applications and other waterproofing solutions.

- Firstly, waterproofing membranes may be installed in vertical and horizontal orientations, i.e., in floors or walls.

- Secondly, they are used behind a wide variety of walls in the exterior wall assembly.

- Thirdly, especially in below grade applications, they are expected to last for the life of the building or structure. Once construction is complete, they cannot be replaced easily if a leak develops.

There is zero tolerance for design failures at the foundation of residential and commercial buildings or infrastructure. Once installed, below grade applications can be difficult and costly to access. Therefore, the highest quality building materials are typically selected for waterproofing solutions, which may include coatings, drainage media, perimeter drainage, interior channels and sump pumps, and other materials and design elements as well as waterproofing membranes.

A membrane ensures that a uniform layer of waterproofing extends across the entire surface. When using liquid applied waterproofing, the thickness may vary depending on the skill of the contractor. Some areas may be several mils too thick, adding waste and cost, while others may be too thin, leaving the structure vulnerable to moisture intrusion.

Considering their critical role, waterproofing membranes should meet and exceed industry standards.

Figure 2 — BG700 waterproofing membrane installed in a below grade application. |

Two Water Barriers in One Membrane

Water Proofing means that moisture is not allowed to pass through the membrane or system. A waterproof membrane is not just semi-permeable. It is impermeable. That means it is a Class A vapor retarder, i.e., it is virtually impervious to the passage of moisture.

A typical waterproofing membrane has a thickness of 60 mils, or 1.5 mm, comprising two water barrier layers. The first water barrier is the modified bitumen material and the second is typically a film laminate. Such laminates are usually made of a polyolefin, such as polyethylene or polypropylene; or sometimes the laminate is a polyester. The laminate in BG700 is a high-strength, cross-laminated, polyethylene film that has exceptional tear resistance and waterproofing characteristics.

Toughness and Durability

A multilayer structure imparts exceptional durability to the waterproofing membrane. The SBS compound in the LeakBarrier BG700 membrane will not crack or dry. The polyethylene film was designed to optimize multiple factors including the tensile and tear strengths as measured using the ASTM D412 and ASTM D882 standards, respectively.

Tensile strength is not the only property of interest in waterproofing applications. The elongation of rubberized asphalt is also important to achieve optimal performance. Elongation is tested according to ASTM D412. Also, resistance to crack formation under cycling at low temperatures is important. This property is measured according to ASTM C836. Other mechanical properties that can be tested according to ASTM standards are pliability, puncture resistance and hydrostatic head. (See Table 2.)

The hydrostatic head property is important for below grade applications. Waterproof membranes must resist moisture penetration by water under hydrostatic pressure, which is the pressure due to the force of gravity on the water.

The long life-cycle of waterproofing membranes depends upon the optimization of these mechanical properties. Tarco’s long experience with the design and manufacturing of premium modified bitumen membranes for roofing applications has culminated in a waterproofing membrane of the highest quality. It is a superior waterproofing membrane for building enclosures and foundations from an industry leader.

The Best that Money Can Buy

You want to recommend the best available waterproofing membranes to home builders, materials specifiers, and contractors. Tarco’s LeakBarrier BG700 is a premium waterproofing membrane and a part of the Tarco LeakBarrier product portfolio. Visit www.tarcoroofing.com for more information.