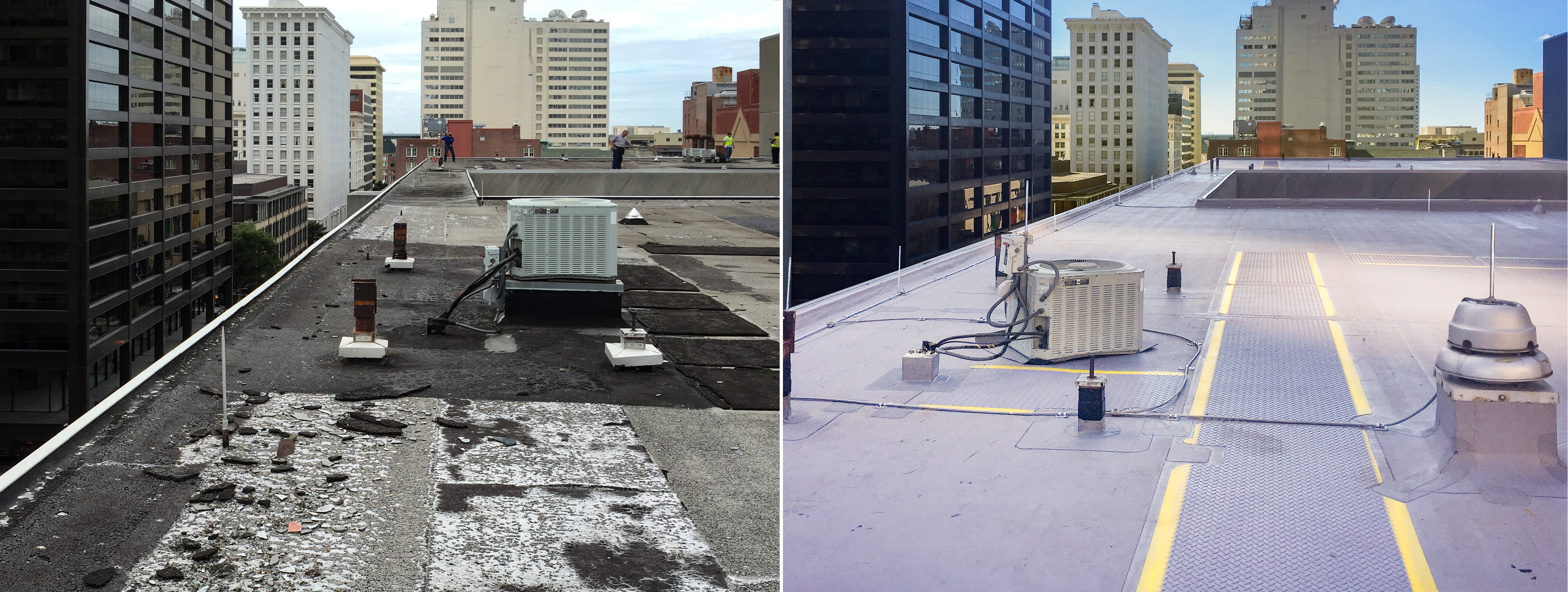

When the Atlanta Fulton County Public Library in Atlanta, Ga. needed to be reroofed (left), the parts of the lightning protection system on the rooftop had to be reinstalled to meet current lightning protection standards (right). Photos courtesy of Atlanta Lightning Protection.

When the Atlanta Fulton County Public Library in Atlanta, Ga. needed to be reroofed (left), the parts of the lightning protection system on the rooftop had to be reinstalled to meet current lightning protection standards (right). Photos courtesy of Atlanta Lightning Protection.

Most components of a lightning protection system can last the life of a structure with little maintenance. Unfortunately, the same cannot be said of typical roofing systems and rooftop equipment; they need routine servicing, occasional repairs, and, all too frequently, replacement. When this happens, consideration must be given to the existing lightning protection equipment on the roof to ensure that the building remains safe from the ravages of lightning.1

Before reroofing can be performed, rooftop elements of the lightning protection system must be removed. Then, after the reroofing, the lightning protection components have to be reinstalled or replaced to restore the integrity of the building’s lightning protection system.

Lightning Protection Components

A lightning protection system provides multiple paths over which the powerful current of lightning can safely pass through a structure and into the ground. In addition to parts of the system located beneath a roof, the following three types of components are typically found on rooftops:

- Strike Termination Devices: These rise above the roof and rooftop equipment to intercept lightning strikes before they reach the building. The most frequently used strike termination devices are air terminals, informally called lightning rods.

- Conductors: These interconnect the strike termination devices with down conductors leading from the top of a structure to the ground. The most frequently used conductors are large-diameter, multi-strand cables.

- Through-Structure Assemblies: These are used where lightning conductors pass through roofing, insulation, and the roof deck to connect the rooftop network to down conductors and the lightning protection grounding system. (Figure 1)

Figure 1. On the roof, a typical lightning protection system includes: 1) Air terminals mounted around the perimeter, along ridges and other high points, on top of rooftop equipment that is not within a zone of protection created by strike termination devices mounted higher on the roof, and within the field of large roofs; 2) A network of conductors that interconnect the air terminals and create multiple paths leading to ground; and 3) Thru-roof assemblies that allow conductors to penetrate the roofing and roof deck. Myriad connectors and fasteners are also required. Image courtesy of East Coast Lightning Equipment, Inc.

Figure 1. On the roof, a typical lightning protection system includes: 1) Air terminals mounted around the perimeter, along ridges and other high points, on top of rooftop equipment that is not within a zone of protection created by strike termination devices mounted higher on the roof, and within the field of large roofs; 2) A network of conductors that interconnect the air terminals and create multiple paths leading to ground; and 3) Thru-roof assemblies that allow conductors to penetrate the roofing and roof deck. Myriad connectors and fasteners are also required. Image courtesy of East Coast Lightning Equipment, Inc.

These components must be UL-listed for use in lightning protection systems. They are located in accordance with ANSI-approved standards including National Fire Protection Association (NFPA) 780—Installation of Lightning Protection Systems and related standards from the Lightning Protection Institute (LPI) and UL. An assortment of fittings, fasteners, and bases are also required to assemble these components; they are typically fixed to roofing and equipment with exterior-grade construction adhesives or mechanical fasteners.

Preparation

The National Roofing Contractors Association (NRCA) cautions, “The installation, evaluation and maintenance of [lightning protection systems] are beyond the expertise of most roofing contractors…” and recommends that the lightning protection work be performed by someone certified by LPI.2 LPI certification require passing multiple rigorous examinations to demonstrate mastery of lightning protection standards and construction methods.3

Qualifications are crucial. Figure 2 shows problems that are representative of lightning protection work performed by unqualified contractors. While some roofers, to be sure, show better craftsmanship, they do not have the in-depth knowledge required to do the job correctly. Further, a roofer that tampers with a lightning protection system is likely to void the system’s certification and become liable for lightning-related problems.

Figure 2. These examples illustrate the types of defects that occur when a lightning protection system is reinstalled by unqualified individuals. Cables have kinks resulting in bends that are too sharp for lightning to navigate. Other cables are strewn haphazardly across the roof and are not secured or connected as required by lightning protection standards.

Right: Photo courtesy of Guardian Lightning Protection.

Left: Photo courtesy of Smokestack Lightning, Inc.

The lightning protection professionals should be on the roof before roofing is torn off to measure and mark the locations of thru-roof assemblies so they can be found after they are covered by new roofing.

At the same time, the lightning protection professional will determine whether it makes sense to salvage and reuse existing components. It requires extra labor to remove parts without damaging them, the old parts may not fit exactly into their original locations nor be compatible with new materials, and it is difficult to determine if the old products still comply with current standards. In most cases, new components will be used; the old components will be recycled for the value of the high-grade copper, brass and aluminum they contain.

While existing components can be salvaged and reused if they are in good condition, using new materials it is generally less labor intensive and provides a better looking result. Photo courtesy of Dominion Lightning Rod Co., LTD.

If a building is to remain occupied during reroofing, it may be prudent to install temporary lightning protection measures. especially if the building contains highly combustible or explosive materials or is used for mission-critical operations. If there will be a hiatus in the lightning protection, the building owner and tenants should be notified in advance so they can take actions they may deem necessary. And an eye should be kept on the weather report so disruptions to the lightning protection can be postponed when thunderstorms are forecast.

The lightning protection installer and the roofer must determine whether the roofing manufacturer has special requirements for the lightning protection system as conditions for getting a roof warranty. The parties should determine, for example, if the proposed adhesives are acceptable to the roofing manufacturer. Some roofing manufactures require application of an extra layer of roofing membrane between lightning protection equipment and the roof membrane. The project specifications should include requirements for documenting that the parties accept each other’s requirements. On large or complex projects, requiring a pre-construction meeting is also advisable.4

Restoring Lightning Protection

NRCA suggests roofers and lightning protection contractors coordinate project schedules and work sequencing to ensure efficient installation of their respective activities and minimize return trips to the job site. Coordination will also be required with other trades as the lightning protection system will have to be installed on high points on the building that are not within a zone of protection.5 Examples can include: parapet copings, ladders, access hatches, railings, signs, antenna, drains, plumbing vents, flues, mechanical equipment, and other rooftop appurtenances. Metal fabrications, such as gutters and flashings, may have to be bonded to the lightning protection system to create electrical equipotential throughout the building and prevent lightning from arcing from a lightning conductor onto another metallic path to ground with lower resistance.

While the lightning protection contractor is on the roof, the building owner should have the contractor check the condition of all parts of the lightning protection system that can be accessed from the roof, even parts that are not directly affected by the reroofing. While components are durable, they can be damaged or become detached due to abuse or harsh conditions. Reroofing provides an excellent opportunity to repair such damage.

Items such as these are primary sites of concern:

- Chimneys can be damaged by corrosion due to exhaust fumes and their heightened exposure to the elements.

- HVAC equipment on the roof can be damaged if mishandled during maintenance. For example, air terminals and conductors mounted on an exhaust hood can be damaged if the hood is carelessly removed to service a fan. (Figure 3)

Figure 3. The conductor cable on this rooftop exhaust was damaged when the hood was removed to service HVAC equipment. Damage like this should be repaired when the lighting protection system is reinstalled. Photo courtesy of Smokestack Lightning, Inc

Figure 3. The conductor cable on this rooftop exhaust was damaged when the hood was removed to service HVAC equipment. Damage like this should be repaired when the lighting protection system is reinstalled. Photo courtesy of Smokestack Lightning, Inc

- Items that have been added to the roof may require surmounting by lightning protection components. This happens, for example, when a building owner or supplier installs a light fixture, security camera, or antenna without the assistance of a lightning protection installer. (Figure 4)

Figure 4: When the camera was installed on the rooftop, the building owner should have had a lightning protection professional extend the lightning protection system to the top of the new equipment. Oversights like this should be remedied when the lightning protection system is reinstalled after reroofing. Photo courtesy of Boston Lightning Rod Co.

Figure 4: When the camera was installed on the rooftop, the building owner should have had a lightning protection professional extend the lightning protection system to the top of the new equipment. Oversights like this should be remedied when the lightning protection system is reinstalled after reroofing. Photo courtesy of Boston Lightning Rod Co.

The integrity of a lightning protection system rests on specifying a three-pronged approach:

- System is designed in accordance with recognized standards from NFPA, LPI, and UL.

- Work is performed by certified installers and contractors. And,

- Acceptance of the completed project is dependent upon the work being inspected and certified (or recertified) for compliance with the standards.

The most widely used certification program is the Lightning Protection Institute – Inspection Program (LPI-IP). If the building is already certified, the reroofed building can apply for LPI-IP’s

Reconditioned Master Certificate to signify that the building’s complete lightning protection system is up to standards. If the existing building is not certified, LPI-IP can issue a Limited Scope Report addressing only work performed in the current Project; alternatively, the building owner should consider getting the entire building certified by bringing both the rooftop and below-roof lightning protection system up to standards. The lightning protection installer is likely to be one of the last trades on a project since the inspection cannot be performed until all the work on a structure is completed.6

The wear on the HVAC exhaust hood and plumbing vent suggests the condition of the roof prior to reroofing. By assuring that all work was done according to standards, the building is now protected against both precipitation and lightning from the sky. Photo courtesy of Atlanta Lightning Protection.

The wear on the HVAC exhaust hood and plumbing vent suggests the condition of the roof prior to reroofing. By assuring that all work was done according to standards, the building is now protected against both precipitation and lightning from the sky. Photo courtesy of Atlanta Lightning Protection.

Roofers and lightning protection professionals face common hazards such as working at heights and exposed to weather. It is imperative that they take shelter when a thunderstorm threatens. As the National Weather Service advises, “When Thunder Roars, Go Indoors.”

References

1. For more about lightning protection, see: www.buildingenclosureonline.com/articles/85718-lightning-protection-systems.

2. The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control - 2022, “Appendix 3 – Considerations for Lightning Protection Systems”.

3. A directory of LPI certified individuals and firms is at www.lightning.org.

4. guide specification lightning production systems for reroofing can be downloaded at https://bit.ly/LightningSpec.

5. See animation explaining zone of protection at http://bit.ly/rolling-sphere.

6. See www.lpi-ip.com.