Q: Why is it important to insulate a building’s below-grade elements?

A: As the saying goes, a team is only as strong as its weakest link—the lack of code-compliant insulation in exterior below-grade applications can compromise a building’s overall thermal performance. Underscoring this point, reports by the U.S. Department of Energy (DOE) suggest that under-insulated below-grade applications can account for approximately 20 percent of a building’s total energy loss depending on building type and location. Importantly, the vulnerability for energy loss via below-grade elements of a building must, in almost every case, be addressed at the time of initial construction.

Insulating below-grade or below-slab applications with high-performing materials like polyiso continuous insulation can address this energy drain and in turn, increase a building’s energy efficiency. Polyiso is a closed-cell foam insulation that offers one of the highest R-values per inch compared to other insulation options. In below-grade applications, polyiso isolates the foundation from ground temperatures, reducing heat loss through floors and basement walls. Polyiso is lightweight and easy to handle and cut on the jobsite. The product is manufactured with durable facers that help to reduce jobsite damage and breakage. Polyiso products are available in a variety of options and project teams should consult with polyiso manufacturers to determine the appropriate product for below-grade applications.

Q: Below-grade applications are susceptible to prolonged water exposure from surrounding soil. How does this factor impact the performance of polyiso products?

A: Yes, demanding environmental conditions that present the risk for moisture intrusion can have an impact on an insulation’s performance and its service life. But in addition to providing proven thermal resistance, polyiso’s closed-cell structure inherently resists moisture—a key performance factor when specifying insulation products for ground contact applications.

To test its moisture performance, an independent laboratory subjected polyiso with its facing materials removed (i.e., foam core only) to various moisture loading and temperature (freeze-thaw) conditions. The test conditions are designed to drive moisture into and throughout the material. The results showed that polyiso experienced only a slight increase in measured moisture content, remaining well below the maximum limit of 0.3 percent by volume typically observed in other common below-grade products. Polyiso’s thermal performance also showed no significant decline even after prolonged moisture exposure.

The experiment highlights polyiso’s inherent moisture resistance as a closed-cell foam and its ability to protect foundations from moisture intrusion. This performance protects polyiso’s long-term durability and its industry-leading thermal resistance properties. This all translates into enhanced building envelope energy efficiency.

Q: In addition to improved thermal efficiency, can polyiso resist the structural loads from the building and ground backfill?

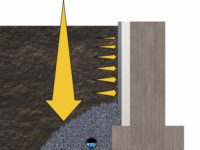

A: Absolutely. While thermal efficiency and moisture resistance are critical in below-grade applications, an insulation material also needs to exhibit excellent compressive strength. Below-grade insulation must perform under various loads, including those created by backfill and hydrostatic pressure. Polyiso is a versatile solution, manufactured and field-proven to deliver the necessary compressive strength, which is derived from the material’s closed-cell foam core. Polyiso products are available with a labeled compressive strength of 25 psi, which meets the performance specifications for most below-grade applications.

Polyiso, as a durable rigid foam board, is manufactured to resist deformation and maintain its integrity when faced with changing environmental conditions below-grade. Polyiso’s foam core and durable facing materials standup to jobsite conditions that include backfilling foundation walls and pouring concrete slabs. This durability also protects a foundation’s waterproofing or damp-proofing from any damage caused by surrounding backfill.

Q: Are there any added performance benefits to using polyiso in below-grade applications?

A: When used below-grade, polyiso plays an important role in meeting or exceeding thermal resistance targets for the building envelope. A building envelope constructed with continuous insulation—from the roof to walls to below-grade—is critical to reducing the load on heating and cooling systems. Improved building energy efficiency reduces energy waste, saves money and creates more comfortable indoor environments.

Polyiso’s high R-value per inch also means project teams can receive more product per truckload reducing the number of deliveries to the jobsite and space required for material staging. These savings add up when you consider material staging prior to and on jobsites. For example, to meet an R-10 code requirement for below-grade insulation, teams will need to specify 2.0 inches of XPS insulation. However, an R-10 can be met with approximately 1.5-inches of polyiso insulation—a savings of up to 25 percent. What does this mean for owners, distributors, and contractors? Twenty-five percent less floor space in distribution warehouses, 25 percent fewer truckloads for delivery, and 25 percent less volume of material for jobsite staging and installation.

Justin Koscher is the president of the Polyisocyanurate Insulation Manufacturers Association (PIMA). For more information on using polyiso in below-grade applications, refer to PIMA’s Technical Bulletin Series on Below-Grade Applications or visit www.polyiso.org.