ESa, formerly known as Earl Swensson Architects, recently moved its headquarters into Gulch Crossing in Nashville, which the firm also designed. Opened in July 2015, ESa now occupies the top two floors of this new, 205,000-square-foot, eight-story, Class A office building. The high-performance curtainwall from Wausau Window and Wall Systems offer unobstructed views of downtown and supports the energy-efficient building’s LEED Gold certification.

Environmental responsibility and energy consciousness are inherent values adopted in the design, construction and operation of not only Gulch Crossing, but also in the surrounding community. The Gulch was the first neighborhood in the South to receive LEED for Neighborhood Development Silver certification from the U.S. Green Building Council. Located near Music Row and Vanderbilt University’s campus, the area has become a sought-after destination.

Gulch Crossing’s sustainable design, efficient performance, prime location and attractive appearance are essential when asking a premium rental rate, the highest rental rate in Nashville. Nearly fully leased, it is the first office building to open in Nashville in the last six years. It also offers 16,000 square-feet of retail on the ground floor.

Situated adjacent to active railway lines and busy bike and pedestrian paths, Gulch Crossing acts as the gateway to an emerging, vibrant, urban neighborhood. Highlighting this connection and heritage, its front entrance, called “The Boxcar,” is set at the same angle as the train tracks. The building’s main lobby included tables made with wood reclaimed from previous train station. In The Club Room at Gulch Crossing, the glass-enclosed, private gathering area provides a transparency between interior and exterior, opening onto a green plaza with an amenity deck.

From the two-story lobby through the eighth floor with ESa’s open-plan offices, Wausau’s curtainwall systems offer Gulch Crossing’s occupants floor-to-ceiling, panoramic views. Working closely with the ESa and general contractor JE Dunn Construction, glazing contractor Alexander Metals, Inc. installed a combined total of 46,500 square-feet of curtainwall and unitized curtainwall.

The curtainwall systems are pre-engineered to ensure the intended performance. Available on an accelerated delivery schedule, these competitively priced curtainwall systems are backed with an industry-leading warranty of up to 10 years.

The company’s unitized curtainwall systems are manufactured in ready-to-install units that span vertically from floor-to-floor. As the curtainwall units are pre-glazed under controlled conditions, rather than at the job site, building teams can be confident that the systems achieve their intended performance along with saving time and labor in the field.

“Using INvision unitized curtainwall, handling for each unit is minimized, which decreases the opportunity for a mishap and saves time overall. Installation time is a fraction of that necessary for field-glazed systems,” explains Corey Trcka, Advantage by Wausau’s wall products manager. He adds, “Alexander Metals was able to install more than 40 units a day.”

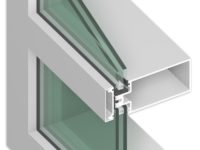

Ensuring a compatible installation and uniform sightlines, both of the aluminum-framed systems used on Gulch Crossing are 7.25 inches deep with a 2.5-inch profile. Further enhancing the exterior appearance, the company custom-made some of the curtainwall cover plates into blade-like shapes.

Beyond aesthetics, the unitized curtainwall has a polyamide thermal barrier that provides enhanced condensation performance and low U-Factor, helping reduce the building’s HVAC peak loads and associated energy costs. For Gulch Crossing, this curtainwall achieves National Fenestration Ratings Council U-Factors averaging 0.37 BTU/hour-square-foot-degrees Fahrenheit with an American Architectural Manufacturers Association 1503 Frame Condensation Resistance Factor of 78.

The curtainwall combines high performance with the recognized benefits of natural light, ventilation and views. Further contributing to this project’s sustainable design goals, the aluminum systems were manufactured with an average of 74 percent recycled content.

Linetec finished the curtainwall aluminum framing and covers using a two-coat 70 percent polyvinylidene fluoride resin-based coating. The Black Onyx color was custom-blended in Linetec’s in-house laboratory. As an environmentally responsible finisher, Linetec captures the liquid paints’ volatile organic compounds to eliminate the exhaust of potential pollutants. Tested to meet the stringent AAMA 2605 specifications, the resulting, durable coating ensures a long-lasting finish.

For the first time in more than 30 years, Gulch Crossing unites ESa’s 185 employees on two open-office concept floors with a communicating stair. The new headquarters showcases the firm’s skillset as well as its brand. Employees were previously scattered over five floors in their former location. As Todd Hilbert, AIA, principal and project director of Gulch Crossing, told Nashville’s The News in July, “In designing our new office, we stepped back and evaluated our clients, staff and project types. We placed employees in an open environment that encourages collaboration between people with the same vision, passion, values and project responsibilities to more efficiently serve our clients.”

Eric Klotz, senior design manager and lead designer of Gulch Crossing, added, “We get to design spaces for clients every day, but, for ourselves, it’s once in an individual’s career.”

- Developer: MarketStreet Enterprises; Nashville; http://www.nashvillegulch.com

- Architect and Interior Designer: ESa; Nashville; http://esarch.com

- General Contractor: JE Dunn Construction; Brentwood, Tenn.; http://www.jedunn.com

- Glazing Contractor: Alexander Metals Inc.; Nashville; http://www.alexandermetalsinc.com

- Glazing Systems—Curtainwall Manufacturer: Wausau Window and Wall Systems; Wausau, Wis.; http://www.wausauwindow.com

- Glazing Systems—Finishing: Linetec; Wausau, Wis.; http://www.linetec.com

- Project Photos By: Attic Fire, courtesy of ESa, Nashville

- Video of Construction: https://vimeo.com/109379204