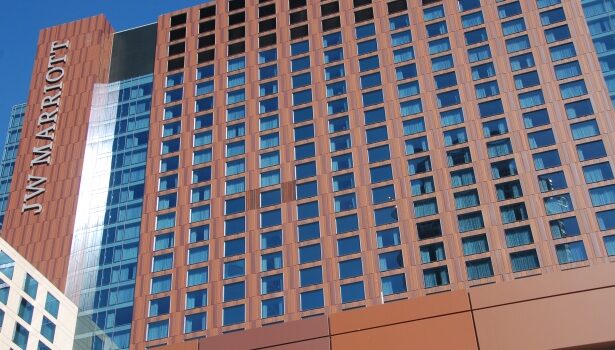

Teamwork and communication led to the successful construction of the JW Marriott in downtown Austin, Texas. McElroy Metal products and partners helped get everyone on the same page to achieve the aesthetic and structural goals of all involved.

“The inspiration came from the look of weathered steel, similar to the Corten steel bridges found throughout Austin,” said Eddie Abeyta, AIA, LEED AP, design principal at HKS Inc. of Dallas. “We wanted to capture that effect, the colors, and the design.”

Abeyta’s original plan was to use actual weathered steel panels of varying sizes and depths. Price estimates led to a search for less expensive alternatives and McElroy Metal. Five sets of three similar colors were selected, all custom colors by Valspar.

“John Kelly of Valspar made all of this happen during the Christmas and New Year holiday season,” said Brad Hitzfield, owner of ProCLAD Inc., of Noblesville, Ind. “McElroy Metal quickly provided us with the 15 colors of sheet stock to make up different mock-ups. We fabricated five separate full-sized mock-ups and delivered them to the architect’s parking lot. He picked out what he liked and we proceeded with panel production.

“The superior thing about the metal panel application (as opposed to weather steel) was that by using three colors that represented the light, medium, and dark ranges of weathered steel, the three colors allowed the modeling effect of weathered steel to be achieved. Getting the three colors right was the trick. The brilliance of Abeyta was to understand that from a distance, the three similar colors of panels would have an abstract, yet similar, visual effect as weathered steel has up close.”

Hitzfield said the panels were designed with a consistent reveal and concealed fasteners. Approximately 40,000 square feet of 18-gauge Galvalume was fabricated flush in three depths and five widths, all in ProCLAD’s shop. The goal was to have the panels provide a hearty and rugged appearance, different from modern monolithic structures. “The shadow lines and the colors add to the dimensionality,” Abeyta said. “We could best get this aesthetic from metal. Metal gives us the ability to achieve an interesting aesthetic appearance.”

Metal was specified because it offers a durable maintenance-free longevity other products can’t match. In addition to a lower upfront cost than weathered steel, the 18-gauge Galvalume offered extended warranties. “The prefabricated/unitized building envelope approach allowed the panels to be delivered ready to install, while saving time and money,” said Abeyta.

Hitzfield explained that ProCLAD crews mounted 75 percent of the panels on back-pans that were glazed into unitized curtain wall. The balance of the panels were mounted on girts in varying locations. The project took nine months to complete.

.jpg?height=200&t=1656702490&width=200)