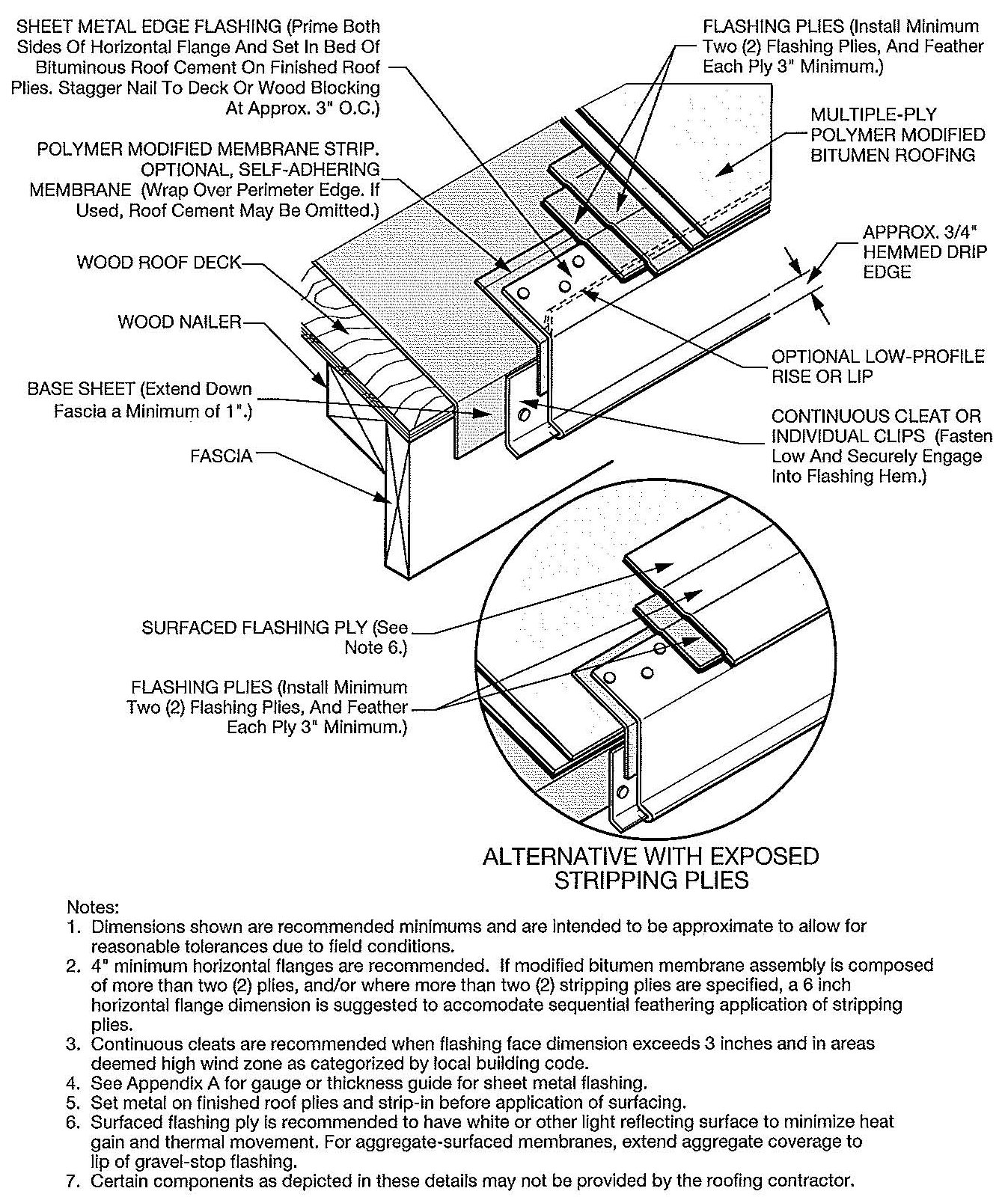

Proper application of the perimeter edge is critical to the success of a roof system (steep- slope or low-slope) due to susceptibility of wind damage. Proper securement of the roof system and perimeter metal is required to eliminate damage from high velocity winds. Proper securement requirements are obtained through completion of perimeter metal calculations. It is also a code requirement that perimeter metal materials are certified by ANSI/ES-1. The IBC code provides further details of these requirements.

The other condition that is extremely important is the waterproofing of the fascia in conditions where the drainage of water occurs at the perimeter. This is a consistent condition in steep-slope applications or low-slope applications that drain at gutters or scuppers.

An important waterproofing requirement is that the base sheet is extended through the perimeter and extends down the fascia a minimum of 1-inch. An additional strip in of flashing material can be applied to the perimeter edge and over the fascia metal prior to the application of the perimeter metal for added waterproofing protection.

Flashing plies shall be set over the perimeter metal flange at the roof surface to strip-in metal and eliminate moisture infiltration to the perimeter edge. The roof membrane is then applied over the completed perimeter flashing assembly as illustrated in the detail.

|

| Photo courtesy of WSRCA |