Research Shows That Garden Roofs Can Reduce Heating and Cooling Costs

A recent study conducted by Oak Ridge National Laboratory (ORNL) and SPRI shows that vegetative roofs can help reduce heat gain and heat losses, resulting in significant energy savings in mixed climates. The reduction in heat gain in cooling dominated periods - and heat losses in heating dominated periods - translates into lower heating and cooling demands for the conditioned space. However, the study notes that the energy savings offered by vegetative roofs are climate dependent and affected by the efficiencies of heating/cooling equipment. ORNL’s testing took place in the mixed climate of East Tennessee.The results of the ORNL study also show that lower membrane temperatures and temperature fluctuations were experienced by the vegetative roofing system than the control black-EPDM and white-TPO roofing systems.

The ORNL research project was initiated in June 2008 by SPRI - the association representing sheet membrane and component suppliers to the commercial roofing industry - to quantify the thermal performance of various vegetative roof systems relative to black and white roofs. “As part of the effort to reduce energy use in commercial buildings, energy codes are greatly increasing the required thermal efficiency of roofing systems,” said SPRI Technical Director Mike Ennis. “It is important to understand the energy savings associated with vegetative roofs so that they can be properly credited in these codes.”

A summary of the ORNL/SPRI study written by Andre Desjarlais, Abdi Zaltash and Jerald Atchley of ORNL and Mike Ennis of SPRI was released earlier this year at the RCI Annual Convention.

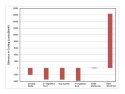

Cooling loads of

vegetated and black roof sections indexed to the white section cooling load.

Increased Demand for Vegetative Roofs

Vegetative roof systems have enjoyed significant growth in the last decade in the United States. The numerous benefits that green roofs provide have helped to fuel their resurgence in industrial and urban settings. For these reasons, it was important that SPRI and the roofing industry quantify the thermal performance of various vegetative roof systems relative to black and white roofs.In addition to energy savings, vegetative roofs offer many environmental and economical benefits. These include:

• storm water retention.

• reducing the urban heat island effect.

• increasing the longevity of the roofing membrane.

• adding plants that enhance biodiversity and filter air contaminants.

• beautifying the surroundings by incorporating green space.

With that said, the goal of SPRI and ORNL in this study was to accurately measure the annual cooling and heating loads per unit area of three vegetative roofs. The study also included side-by-side comparisons with black and white roofing systems, as well as a test section with just the growing media without plants. The low-slope roof systems were constructed and instrumented for continuous monitoring in the mixed climate of East Tennessee.

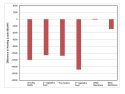

Heating loads of

garden and black roof sections indexed to the white section heating load.

Classifying Vegetative Roofs

Vegetative roofs are typically classified as “extensive” or “intensive” systems. Extensive vegetative roofs use a shallow substrate layer (up to 4 inches); feature low growing plants such as drought tolerant sedum and grasses; and require minimal maintenance. In contrast, intensive vegetative roofs require deeper substrate layer; use a wide variety of plants such as trees and shrubs; and require high maintenance and an irrigation system. Both types, including a tray system, were used in the ORNL testing.The vegetative roof systems built by ORNL included a commercially available modular vegetative roof system (nominal 4-inch tray system), a nominal 4-inch typical roof vegetative system, and a nominal 8-inch intensive depth vegetative roof system. In addition, a nominal 4-inch system with typical soil and erosion mat (but no plants) was installed for side-by-side comparison with the vegetative systems. The results showed that all the vegetative roofs reduced heat gain (lowered cooling loads) compared to the white control system due to the thermal mass, extra insulation, and evapo-transpiration associated with the vegetative roof systems.

The 4-inch and tray vegetative roof systems reduced the heat gain by approximately 61 percent, while the reduction with the 8-inch vegetative roof was found to be approximately 67 percent.

The study also found that the vegetative roof systems were more effective in reducing heat gain than in reducing heat losses (heating loads). The reduction in heat losses for the 4-inch and tray systems were found to be approximately 40 percent in East Tennessee. Again, it should be noted that these values are climate dependent.

Vegetative roofs also reduced the temperature (heat exposure) and temperature fluctuations (thermal stress) experienced by the roof membrane.

In the cooling season of East Tennessee, the average peak temperature of the 4-inch and tray systems was found to be approximately 94° Fahrenheit cooler than the control black roofing system. The average temperature fluctuations at the membrane for the 4-inch and tray systems were found to be approximately 10°F compared to 125°F for black and 64°F for white systems. As expected, the 8-inch vegetative roof had the lowest fluctuations at approximately 2°F.

During the heating dominated period of East Tennessee, average peak membrane temperature of the white roofing system remained approximately 56°F cooler than the black membrane.

The 4-inch, 8-inch and vegetative tray systems were found to be approximately 70°F cooler than the black. In addition, the growing media was found to be approximately 65°F cooler than the black system. The average temperature fluctuations at the membrane for the 4-inch and tray systems were found to be approximately 8°F compared to 109°F for black and 55°F for white control systems.

The average temperature fluctuation in the growing media was found to be slightly larger than the 4-inch and tray systems at approximately 12°F. The 8-inch vegetative system had the lowest fluctuations at approximately 2°F.

“Under the climate conditions that the test were performed, the energy benefits of all the vegetative roof systems evaluated were greater than a traditional ‘cool’ roofing membrane,” said Andre Desjarlais of ORNL.

SPRI recognized that there was an increasing need for a comprehensive energy analysis that is successful at modeling vegetative and white roof technology while taking into account the yearly climatic conditions across the United States and the building envelope. Well-characterized test data from side-by-side comparison of vegetative and conventional low-slope roofs were essential for creating a successful model for this testing.

The vegetative roof research project at ORNL was initiated in June 2008 to quantify the thermal performance of various vegetative roof systems relative to black and white roofs.

Diurnal behavior of

heat flux measurements (April 24-29, 2009).

Test Procedures

Two 4-foot-by-8-foot test panels on the Roof Thermal Research Apparatus (RTRA) were used to construct 4-foot-by-4-foot test sections for the vegetative roofs. Another 4-foot-by 8 foot test panel on the RTRA was used for an exposed black ethylene propylene diene monomer (EPDM) membrane (4-foot-by-4-foot test section) and an exposed white thermoplastic polyolefin (TPO) membrane (4-foot-by-4-foot test section). These were the control systems for the testing.Moisture content was measured with dielectric sensors located in the middle of the growing media in all the vegetative roof systems, including the test section with no plants. This sensor measures the dielectric constant of the soil in order to determine its volumetric water content.

Heavy watering was initiated during the initial installation of the vegetative roofs. During the first several months (June 13, 2008, to October 2, 2008), the vegetative roofs were watered twice a week for approximately 10 minutes. This allowed the plants (various species of sedum) to be established in the test climate of East Tennessee. Plant coverage was about 65 percent of the total area of the 4-inch vegetative roof.

The thermal performance data were analyzed using a dead band in outdoor temperatures between 75°F and 60°F when the building does not require heating or cooling. Therefore, the following definitions were applied to the heat fluxes through the fiberboard insulation: The heating loads (heat losses) were defined as the summation of all the negative heat fluxes when outdoor air temperature is less than 60°F, and the cooling loads (heat gain) were defined as the summation of all the positive heat fluxes when the outdoor air temperature is greater than 75°F.

As expected, the majority of the cooling loads occurred from the second week of April to the second week of October. The average cooling load of the growing media was found to be approximately 38 percent greater than the average cooling load of the 4-inch vegetative roof system.

The analysis continued with a comparison of the cooling load between the vegetative roof systems (including growing media without plants and the black membrane) to the white roofing system. This was accomplished by subtracting the cooling load for the white membrane from the corresponding cooling load for each vegetative roof system. Positive values for this difference represent more cooling requirement for the subject system than the white.

As expected, the black system showed the largest cooling load (largest heat gain) compared to the white system. The cooling loads of 4-inch vegetative and tray systems were found to be similar, with a reduction in heat gain of approximately 61 percent compared to the white control system.

The reduction in heat gain for the 8-inch vegetative roof was slightly higher (approximately 67 percent). This is due to the additional thermal mass and extra insulation provided by the additional growing media for the 8-inch vegetative roof system.

In addition, the reduction in heat losses for the 4-inch and tray systems were found to be approximately 40 percent compared to the white control system. The reduction in heat losses for the 8-inch vegetative roof was slightly higher at approximately 55 percent. This is again due to the additional thermal mass and extra insulation provided by the additional growing media for the 8-inch vegetative roof system.

Diurnal behavior of

membrane temperatures (April 24-29, 2009).

Future Research

In the future, SPRI and ORNL hope to model the internal heat flow for the vegetative roof systems with the STAR computer model in the test climate of East Tennessee.STAR is a transient one-dimensional finite difference model for heat conduction. The model simulates heat flow in multilayer roofing systems. This will require materials with known properties, such as thermal conductivities and specific heats.

STAR has been successfully used to model systems in previous projects. The validated STAR computer model will be used to predict energy use in roofs with different insulation levels and in climates different from the test climate. Future work will also include evaluation of R-value trade-off in these systems.

For more information about SPRI and its activities, visit SPRI’s website, www.spri.org, or contact the association at info@spri.org.