Building codes dictate most aspects of industrial warehouse construction. Most architects, developers and contractors follow the International Building Code (IBC), and in California, the CBC (notorious for its extra tight restrictions, regulations and enforcement). From fasteners to glazing, all materials are addressed by building code.

How do you ensure the building materials are code compliant? One method is by referencing its International Code Council (ICC) Listing. ICC evaluates building materials for performance criteria that meet code requirements. If a product is ICC-ES Listed you can trust it complies. Listed items come with an ESR number (i.e. ESR-3837 for unit skylights). All products in the building spec should be accompanied with an ESR number.

There is no exception for industrial skylights. They are integral parts of the building envelope. Industrial skylights help building owners capitalize on free natural light thus saving on energy costs, raising employee morale and adding much needed ventilation if venting technology is incorporated.

Not all skylights are created equal. More importantly, not all skylights are code compliant. Over the years, some manufacturers have strayed away from following building code and began to offer cheaper products that do not comply with IBC and CBC. The designs and materials used in skylights have become so convoluted that manufacturers think they can deliver non-listed products without notice.

How do you protect yourself against non-compliant skylights? The details and makeup of the skylight need to be identical with the details laid out in the ICC Listing. For example, there are zero industrial skylights approved for a capless system yet some manufacturers offer a capless skylight and pass it off with the ESR number for their ICC-Listed models. Never accept a capless skylight for your building, the domes crack within 5 years and fall risks are very common.

Using non-listed skylights is a very dangerous and costly game. Best case scenario with non-listed skylights is the domes will crack, worst case is works are put in harm’s way. The liability of using cheap non-listed products is not worth the up-front costs savings on the front-end and liability on the back-end.

Another example of manufacturers side stepping code requirements is in the glazing materials. Each manufacturer is approved for a very specific glazing material (i.e. Skyco Skylights industrial skylight is approved for their standard Skypro polycarbonate dome, with 800 pounds impact testing). Without doubt, polycarbonate is the superior glazing material for industrial skylights, but most manufacturers are only approved for acrylics.

Image 1: Non-Listed Capless unit example. A capless unit is when the screws are fastened through the glazing typically causing cracks and weakening the dome. There are zero code compliant capless units.

There are 7 primary details covered in an ICC-ES Report. You can easily find the ICC-Listing by searching for the ESR number. Each detail is briefly explained below:

Approved Sizes: Industrial skylights are most commonly used in the 4-foot by 8-foot size. The sizing in an ICC report is listed as the inside curb dimension so 48 inches by 96 inches. You will typically see it listed as 4896 in model names. An industrial skylight must be exact to what was listed in the report. The reason is bigger skylights use thicker glazing. When you downsize to a 4896, the manufacturer will use thinner glazing. The frame size and thickness of the dome must be exactly as it’s reported in the listing.

Approved Frame Material: Currently all industrial skylights are approved for Aluminum frames. Aluminum helps reduce the weight of the unit down.

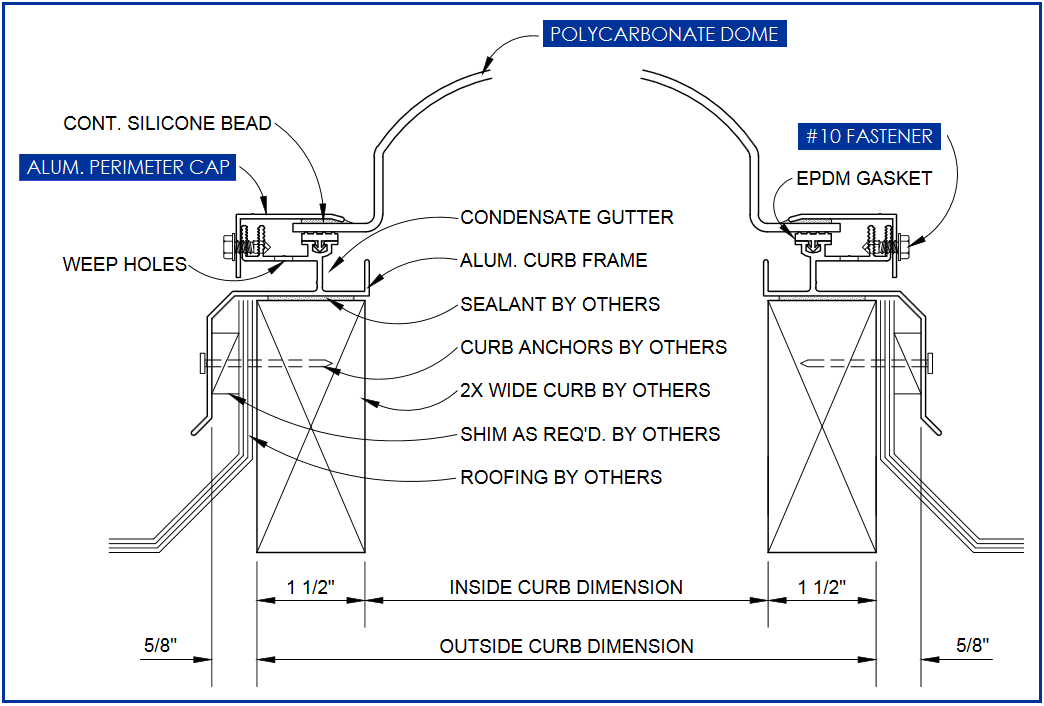

Approved Encapsulating System: This is referring to how the dome is fastened to the frame. There are zero approved capless systems. The only approved system is one with a capped dome. This is when a cap is fastened down through the metal (not the glazing) holding the glazing to the frame. Note: The capless image above (Image 1) shows the exposed edges of the glazing. This does not comply with air and water infiltration requirements. If you ever receive capless units please alert your supplier.

Drawing of an approved capped polycarbonate industrial skylight.

Approved Glazing Material: Each manufacturer is approved for different glazing materials. For example, Skyco Skylights’ industrial skylights are approved for a polycarbonate dome. Polycarbonate is known for its superior strength and long-lasting qualities. If a skylight has a glazing material not listed in its report then the skylight is not code compliant. If you require polycarbonate for glazing, make sure the brand you choose is approved for polycarbonate domes.

Approved Dome Shape: The ideal shape for a dome is the parabolic shape. This shape has a wave design with varying amounts of peaks. Not all manufacturers are approved for a parabolic shaped dome. It is important to make sure which shape the skylight is approved for, parabolic or smooth.

Approved Glazing Layers: Depending on your climate, your industrial skylights will need single or double-glazing layers. It is important to make sure if you need a double dome glazing that the skylight is approved for it. Most skylights are only approved for either a single dome or a double dome.

Approved Mounting Type: Will the skylight be mounted onto a curb? Or is it self-flashing? Like all the other details, it’s vital to make sure the mounting type is listed for that skylight. Note: If the skylight will mount a venting base (or louver), most manufacturers are not listed by ICC for venting bases. Check with the ESR number to make sure a vented base is approved. In approved ICC Listings, the venting base drawings are included in the report.

ICC-Listings can be confusing. Most people don’t have the time to read through ICC documents; double checking which products they received. They rely on manufacturers to supply code compliant products. In some cases, this kind of integrity has gone by the way side in trade for lower costs due to the pressures of competitive bidding.

The first step to addressing this issue is by reviewing building spec’s for accurate ESR numbers that match model names. If the ESR number matches the skylight model name, estimators can accurately request quotes from manufacturers. The next step is making sure the manufacturer is quoting the exact product specified by the consultants or architects. Finally, project managers need to make sure the products delivered are exactly as ordered.

Recent Comments

These are actually very helpful tips. It is...

This is the most beneficial blog for all...

This blog is a great resource for anyone...

Thank you for sharing this important information. I...

This is a very interesting subject of the...