As the current U.S. Administration struggles to articulate a cogent response to irrefutable climate change and lurches out of the Paris Agreement, it falls to states, cities, municipalities and individuals to step into the serious breach of leadership and take up the work of rescuing our world. In the U.S., over 40 percent of energy is consumed by buildings; as a stakeholder in a small design firm, I’m painfully aware of the small role I have to play in the scheme of things. And, yet it will be through the efforts of hundreds of thousands like you and me that we will literally build a cleaner, more secure and more sustainable world. We can all look to the small but important ways that we can contribute to a positive future worthy of our aspirations.

For buildings under about 50,000 square-feet, or for larger “thin” buildings whose cores are proximate to their skins, climate energy loads dominate over internal ones. That is, small or thin buildings’ energy performance is largely, though not entirely, given by their responsiveness to climate. For large buildings, internal loads—occupancy, equipment and lighting—generate most of the energy that building systems must mitigate for thermal comfort. Even large buildings, however, may have zones that are heavily influenced by climate. Designing for climate is therefore critical for any responsible architect. Furthermore, climate-indexed design provides ready opportunities to find formal expressions that are functional, while beautiful.

Moreover, architects and other building design professionals availing themselves of newer design processes now have at their disposal powerful digital tools ranging from computational design, energy modeling, to building information modeling (BIM). The latter is commonly seen as a software tool or environment intended to enhance design stakeholder collaboration, reduce coordination errors, increase the efficiency of construction documentation and improve construction processes. As important to the building industry as these benefits are, the use of BIM for design (as opposed to documentation or construction) is often underappreciated.

This article points to design uses of BIM for the development of high-performance buildings with an emphasis on envelope design for skin-load dominated buildings. While our Austin, Texas firm uses Vectorworks Architect as our end-to-end BIM authoring solution, BIM is actually a workflow rather than a particular technology. While your mileage may vary, there are similar tools to the ones described here in other BIM platforms.

Orientation Matters: Micro and Macro

Façade design is predominantly concerned with the highly technical details of wall assemblies, appropriate to program, budget, building typology, energy code compliance, architectural intent and the building’s general climate zone. The façade design team must consider issues of thermal performance, water mitigation, hygrothermic characteristics, constructability, durability and maintenance, budget and appearance. The rubber meets the road in the wall section and detailing of the wall assembly, with particular concern for careful product specification. These are granular issues that are commonly resolved in 2D drawings without particular use of BIM.

Yet the wall section alone does not tell the whole tale. A building’s ratio of north-south envelope to east-west wall area, general orientation, glazing percentage and overall thermal conductivity, as well as passive seasonal shading or solar rights are critical to building energy performance. These macroscopic issues can be analyzed and optimized with a quantitative approach to validating qualitative design decisions. This is but one area where the “I” in BIM can be employed for more than merely, say, rapidly coordinating door and window schedules. BIM authoring software generates geometric models of buildings, incorporating inherent quantitative characteristics of building components, from surface area of roof over conditioned space to total glazing. And, built-in BIM tools allow the designer to leverage that data to make more informed design decisions.

For example, within the BIM file itself, a Heliodon tool (or similar sun-simulating virtual light source) can be effectively used for a number of static or animated sun studies to design effective shading devices that deny summer (or even autumnal) solar heat gain while encouraging passive heating in winter, predicated on appropriate placement of windows and correlated roof overhangs. If the BIM model is structured and organized properly, total south-facing glazing can automatically be compared to exposed internal thermal mass to determine if the winter sun will under- or over-heat a space.

U-factors can be applied to those windows and the total envelope can be analyzed for energy code compliance, even at early design stages when specific wall assemblies have yet to be detailed, as a goal-setting measure. And when the designer needs to go beyond built-in and hand-coded analysis tools (the latter can be as simple as embedded spreadsheets that directly query the model’s geometry for inputs), BIM files can be exported and further investigated by dedicated energy analysis tools. Ideally, this analysis happens early and often for rapid design feedback at critical design phases when changes are far easier to effect.

Figure 1. BIM sun studies combined with real-time comparison of south-facing glass and internal thermal mass can inform the designer’s decision-making early in the design process.

Case Study Vignette: Boussoleil Residence

A data-driven BIM workflow was used throughout the design, documentations and construction of this detached 2,500 square-feet rural residence:

- Sun studies were undertaken throughout early design iterations, concurrently with cut-and–fill analysis of the intelligent site model, in order to strike a balance between optimal sun shading and PV collection on one hand, and minimizing site work on the other.

- Total south-facing glazing was compared to exposed thermal mass surface area to optimize winter passive heating, again as the design evolved.

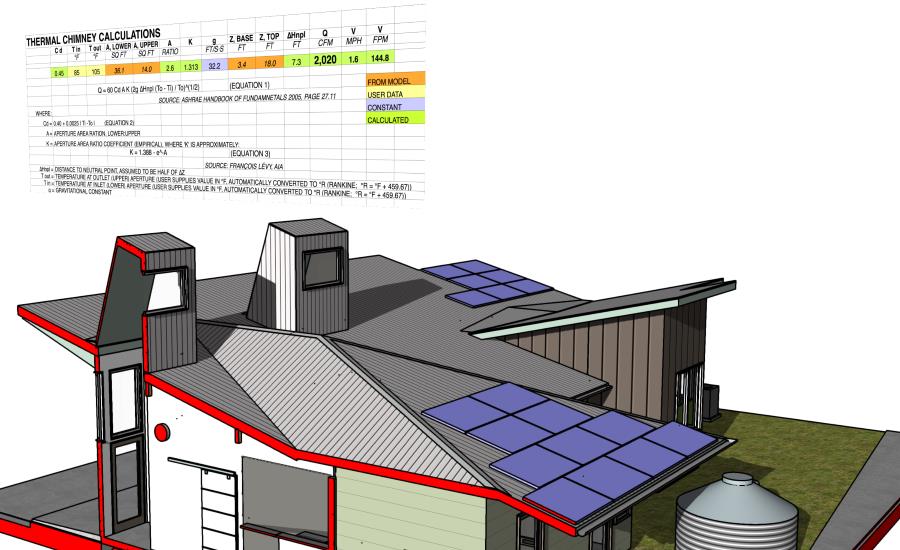

- A thermal chimney used the stack effect of warm air’s natural buoyancy to provide passive ventilation under warm conditions. The chimney’s effectiveness was estimated using established ASHRAE formulas and data provide by the model’s geometry. As the design evolved, the chimney’s effectiveness was balanced with window cost, total height and architectural aesthetics, all within the Vectorworks BIM file.

- A custom “rainwater harvesting tool” (an embedded spreadsheet querying the building’s projected roof area and garden areas) calculated the optimal cistern size throughout the design process (cisterns are about a dollar per gallon, so oversizing one can be an expensive mistake).

- Detailed material takeoffs were shared with prospective contractors for accurate bids and cost feedback.

Figure 2. A thermal chimney represented in BIM with an embedded air flow calculation tool helps estimate cooling effects of this passive feature without resorting to complex computational fluid dynamic (CFD) finite-element modeling (FEA).

Figure 3. A custom rainwater-harvesting tool (really a BIM-embedded worksheet) dynamical calculates an optimal cistern size given the projected roof area of the roof. As the design evolves, the cistern sizing tool can be updated at the click of a button.

Too Much Too Late?

Energy modeling is a critical design factor for many projects, even if many smaller buildings would not seem to warrant it for reasons of cost, or its novelty to smaller-scale design workflows. Moreover, proper energy modeling requires detailed inputs on mechanical systems and patterns of occupation; that data may not be available earlier in the design process. By the time that information is available, it may be too late to make significant improvements to the project’s performance. This case of too much data too late in the design process may be exacerbated by the tendency to delay verifying energy code compliance until late in the design process. It’s a little late to change a wall assembly design just before issuing for permit.

As with most aspects of building design, envelope energy performance should be considered in Schematic Design (SD), refined in Design Development and detailed in Construction Documents. Fortunately, architects have BIM energy analysis (as distinct from energy modeling) tools at their disposal. Whereas energy modeling implies a comprehensive simulation of thermal performance, energy analysis makes more general, yet valid assumptions and calculations concerning building performance without resorting to full FEA (finite element analysis) of the model.

Commonly available built-in BIM tools like Vectorworks’ Energos allow the designer to make conceptual energy analyses at early design phases. For example, the architect can stipulate envelope assembly R-values/U-factors as prescriptive targets in SD, then substitute specific wall assemblies for generic ones as the design is developed. Simply by substituting one wall type for another, competing hypothetical scenarios can be compared and the benefit of a proposed change evaluated. By the time granular energy modeling is deployed, the design has already been vetted at a coarser level, avoiding the pitfall of “too much analysis too late.”

Case Study Vignette: Elgin Residence

Our firm was engaged to design a single-family home in Elgin, Texas, a small town outside of Austin. Like many owners these days, our clients were very concerned with the energy performance of their new home, and they possessed a level of physics and engineering knowledge beyond what is typical. Their technical engagement in the design process was unusually high, and that only improved the project as we were challenged to think carefully about all our design decisions. Accordingly, we designed the house with our characteristic concerns for climatic responsiveness:

- Passive orientation, window and roof overhang design based on sun studies to minimize summer and fall solar heat gain;

- Passive cooling with cross-ventilation and a thermal chimney;

- Tall spaces for thermal stratification (a vernacular design response to Texas climate);

- Rainwater harvesting, to be incrementally phased in.

Figure 4. An architectural rendering of the Elgin Residence.

In addition, on this particular project, wall and roof assemblies were designed with appropriate overall thermal detailing and continuous insulation to defeat thermal bridging. Designing for thermal breaks requires attention to detail, some additional costs and careful installation of wall assemblies. Moreover, defeating thermal bridging is increasingly important in energy efficient design, the greater the indoor and outdoor temperature differential. While 105 degree Fahrenheit days in Central Texas’ Climate Zone 2 are not uncommon in the summer, that’s still a far lesser temperature differential than the 70F or more that you would find on a winter day in, say, Climate Zone 6.

Thermal breaks are always good practice in theory, but expensive or exotic details may not always be cost-effective in warm or mild climates. As for many of our projects, we used BIM energy analysis to compare envelope performance with and without a thermally-broken roof assembly, helping us better inform our client as to the quantifiable impact of implementing additional continuous insulation in the roof. As it turned out, our model showed less than a 1 percent improvement in roof envelope thermal performance.

While that analysis may not be predictive of real-world performance—neither is energy modeling incidentally—it does provide a useful and reliable measure by which to validate design decisions. In other words, BIM-embedded energy analysis can help architects weigh the relative merits of alternative design options, and design accordingly.

Figure 5. From our Energos model, we calculated an envelope loss of 25,322 Btu/FT2/year for our roof assembly: metal roofing, open-cell spray foam insulation in the vaulted roof cavity roof and thermal bridging at rafter/decking connections. A similar roof that was thermally broken assembly yielded annual losses of 25,086 Btu/FT2/year —less than a 1 percent improvement.

Conclusion

Architects and designers who are willing to adopt BIM as part of their design workflow as more than merely “better, faster CAD” can find new ways to expand their design practices and processes. BIM data (the “I” in BIM) can help the designer quantitatively validate qualitative design decisions, yielding improved building performance, as well as opportunities to formally express architectural responses to climate (climate-indexed design). This is indeed an exciting time to be designing.