Acoustics and noise control are important considerations in construction today. Multifamily residents don’t want to be bothered by street noise or neighbors, and schools and hospitals require good sound control to deliver effective learning and healing environments. Designers and builders are all continually searching for information on the best way to cost-effectively meet sound control goals. Among the info they need is reliable data on the acoustic performance of different products and systems and guidance on how to interpret this data.

Noise Control Rating System

One of most common goals for sound control is to keep sound from traveling from one space to another. For walls (and floors), the main way we describe this performance is with the terms “transmission loss” and “sound transmission class” (STC). Transmission loss is how much sound is reduced as it travels through an assembly and STC is the single-number rating we are probably all more familiar with. STC is a measure of transmission loss; the higher the STC rating, the more noise is reduced.

Basics of Noise Control

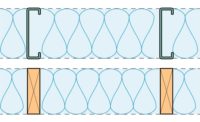

When sound travels through a wall, it takes many paths through both the framing and the air in the cavities, to get from one side to the other. If we want to reduce the sound that can pass through a wall, there is a short list of design changes we can make:

- Make the wall thicker;

- Use heavier materials (concrete block or more gypsum);

- Add absorption in the framing cavities (this is where insulation comes in);

- Add a vibration break (e.g. resilient channels, isolation clips, or acoustical gypsum board).

Air-sealing, which is more of an installation factor, is also important.

Wall Acoustical Data

When we look at listings of walls with STC ratings, these values are all based on lab-measured values. This is done for consistency to eliminate the host of uncontrollable elements that go along with real buildings. This way, we can compare wall systems based on their design and materials.

Insulation and STC

The main job of insulation in a wall, when it comes to noise control, is sound absorption. The air inside a framing cavity acts as a spring, transmitting vibrations from one side of the wall to the other. Insulation acts as a shock absorber on that spring, reducing the amount of sound energy that can take that path. As we would imagine, materials that are good sound absorbers work well for this purpose, and that is where fiberglass and mineral wool come into the picture. Because they’re air-permeable, sound waves can easily penetrate into the material, rapidly losing energy as the sound waves “rub” against the fiber networks.

This brings us to the question of foams versus fibers. The short answer is open-cell foams perform about the same, acoustically, as fiberglass and mineral wool. Closed-cell foams perform worse. Since cavity insulation works as a sound absorber, this makes perfect sense. Open-cell foams should (and do) allow sound to penetrate the material, providing absorption. Closed-cell foams, which tend to be rigid, are very poor sound absorbers, and result in lower STC values.

As a manufacturer of both fibrous insulation and foam, we are aware of all the anecdotal claims and stories from the field about spray foam homes being very quiet. Putting personal perceptions and biases aside, the main differences come down to air-sealing. In the lab, where STC ratings are generated, walls are air-sealed. Walls in real buildings may or may not be.

Several years ago, Johns Manville measured the sound transmission loss and STC ratings for a number of wood-framed exterior walls, with both fiberglass and spray foam cavity insulation. All walls were sheathed with OSB on the exterior and gypsum board on the interior. We also looked at 2-by-4 and 2-by-6 framing. A few examples are shown below. These examples don’t include any cladding, since there is such a wide variety available, and heavy materials like brick would affect the results dramatically. All seams in the OSB and gypsum boards were carefully sealed with either tape or acoustical caulk.

- 2-by-6 framed walls

- R-19 fiberglass batts STC 45

- 5-inch closed-cell spray foam STC 37

- Hybrid 1/2 spray foam + R-13 batts STC 44

- 2-by-4 framed walls

- R-13 fiberglass batts STC 38

- Open-cell SPF STC 38

The results show what we would expect: thicker, 2-by-6 framed walls perform better than 2-by-4, and absorptive insulations perform better than rigid, closed insulation. Just as is seen in thermal performance, quality installation and air-sealing eliminates many of the perceived differences between insulations. The same walls, air sealed and then insulated with fiberglass or mineral fiber, would test and sound as good or better than the spray foam walls, and likely at a lower cost.