Previously posted on ATAS International Inc.'s website.

Weatherproofing is a simple concept at its core. It is any system used to protect a structure from the elements, such as wind, temperature and precipitation; anything that may hurt the integrity of the structure itself.

There are different forms of weatherproofing but almost every structure from shed to home to skyscraper has a form of weatherproofing for protection. A common example of this is the various types of siding. These external layers are designed to protect the interior material from the elements. Without the proper weatherproofing, damage and premature aging of the core structure and its supports could result. These common sidings are what’s called single layer systems. That is, it is a single layer of a material used to keep out moisture, protect from wind damage, circulate air and also be seen as part of the aesthetic design of the building. These single layer systems have their limitations and due to this, other systems have been created that use multiple layers of material to enhance all aspects of weatherproofing. These systems are sometimes described as rainscreen systems; however, even under this category there are significant differences. One of these systems that obtain superior results in aesthetics and in weatherproofing is the Drained/Back Ventilated or D/BV system.

The D/BV System

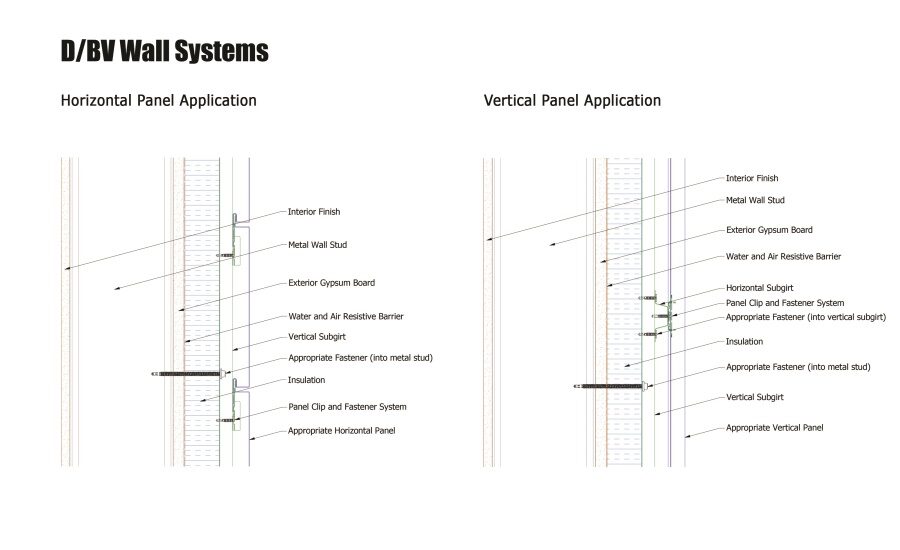

The design of the D/BV system consists of two main parts, which are often described as the outer leaf and inner leaf. These two parts are what separates this system from the single line barriers in name, but in function there is even more of a difference. In fact, there are three distinct sections that make up the D/BV System. The first of these sections is the outer leaf or, exterior cladding. This section is both the aesthetic layer of the system and also the first layer of protection. Between this layer and the inner leaf is an air space. This space is the drainage plane and ventilation cavity. The inner leaf then is comprised of insulation, an air and water resistive barrier and the building structure. Each section of this two-stage design has a very specific purpose. This is where the engineering of the system shows its major benefits.

In the outer leaf, consisting of the exterior cladding, the purpose is to manage and control and in some cases, prevent water infiltration. This exterior cladding specifically is a series of sheets or panels attached to vertical supports to comprise an exterior layer. The joints between each panel may be open or sealed to obstruct or minimize water penetration by kinetic energy and wind force. This system is actually designed to minimize, but not prevent, water penetration. This is because even in sealed systems water penetration is inevitable. Therefore, the design of this system accounts for it and manages it, rather than trying to prevent it. The level to which water infiltration will be managed is dependent upon the wind and environmental load resistance of the structure and environment in which it is built. This exterior cladding also provides UV protection for all of the interior components. This layer works well to protect the interior components, ensuring their integrity and longevity.

From the exterior cladding the next step in is the air space. This air space, far from being an afterthought, is actually a critical design feature of the D/BV system. This air space is designed as a ventilation cavity that provides airflow through the panel system. It allows for proper evaporation of moisture and also allows for the proper pressurization that can sometimes be a problem of the semi-sealed systems. The biggest asset of the air space is that is it also the drainage plane for any heavy precipitation that may get through the exterior cladding. So in times of high wind and heavy rain, the water will always be moving, never pooling or staying trapped in any section of the system. This proper drainage is hugely important in preventing water damage that can cause massive problems over time. The amount of space needed for this varies with the type of cladding used. However, with metal cladding, due to its low porosity, the cavity depth is often only between .375 and .75 inches.

The next step past the air space is the insulation of the panel system and the start of what is referred to as the inner leaf. There are three purposes for this insulation. The first is to reduce heat flow into and out of the building. This allows for a more consistent temperature within the building, therefore making any building using the D/BV system more energy-efficient. The second purpose is to also act as a further water barrier by being comprised of water resistant materials. This is again to ensure the proper flow and drainage of moisture, to have it constantly flowing down and away from the structure. The third purpose is to minimize the chance of condensation and thermal bridging. Condensation and thermal bridging alone can hurt the physical integrity of the building and can create air problems inside and outside of the structure. The proper insulation keeps these concerns from being a factor.

The next layer of this system is an air and water resistive barrier. Due to the fact that water has the potential to get into the wall system, this barrier is the last and most critical line of defense against water infiltration. It is also used as a way to minimize condensation through vapor transmission. The type of barrier used varies depending on certain factors that include the climate that the building is in and the intended use of the building. For example, a building in a desert region with relatively low winds and moisture/humidity has different resistive barrier needs than a building in a subtropical region that may encounter heavy winds and high moisture/humidity. The final element of the wall system is the building structure. This is commonly a brick or block wall assembly, or wood or metal framing, which may also incorporate an exterior facing such as plywood or gypsum board. These very common building structure materials point out that this system does not require any unique or obscure building materials to be effective.

The Pressure Equalized Rainscreen System

There is another system often used that incorporates similar principles into its design; this system is called the Pressure Equalized Rainscreen system (PERS). The PERS system is typically more design intensive. This system works by allowing both static and dynamic equalization. It is an attempt to negate any negative pressure that could draw water into the system. This is accomplished by openings in the cladding that create pressure compartments. The idea is that with the correct pressurization, water will not be able to flow through the system, creating the desired weatherproofing. However, this has been shown to be much more design intensive in order to perfect, especially in areas of more extreme weather and varying types of condensation. Due to this, and the system’s lack of built in back up weatherproofing in case of the system failure, it is held to a fail or pass standard through test procedures. This means that the system is tested and if it fails to eliminate moisture penetration it must be redesigned.

The ventilated and vented wall assemblies of the D/BV system instead incorporate water drainage into its design with the air space between the outer and inner leafs. Moisture inside the system is expected and can be drained. That moisture can occur from several sources, including: water passing through the exterior cladding, water vapor in the air, either from diffusion and or air movement through the wall, and also moisture from within the materials used during the construction cycle. The ventilated and vented assemblies allow for all of these moisture concerns to be drained properly. This proper drainage also has the added benefit of minimizing potential for rot, mold growth, corrosion and discoloration of building materials.

In these types of assemblies, metal is the preferred material; this is due to its low absorption value, and therefore can have a smaller air cavity and less effect on overall design. This in turn means greater freedom in creative and aesthetic design of the building while still providing maximum weatherproofing abilities. Within these metal assemblies there are two types used, one being ventilated and the other vented. The difference between the ventilated and vented walls that are incorporated in the D/BV system is minimal. The ventilated wall has openings at the top and bottom of the air cavity to promote air circulation through the cavity. A vented wall only has the openings at the bottom of the air cavity. This still provides drainage but has reduced volume of air circulation. Choosing between the two will again be based on environment and building needs; however both are effective and have the same design possibilities.

The D/BV system is on the cutting edge of building weatherproofing and is a system that continues to evolve. The always advancing metal wall cladding materials are becoming more widely used due to the ever increasing possibilities in form and aesthetics, from materials to colors to shapes. The D/BV system allows for beautiful buildings to be incredibly protected for structural integrity while maintaining design intent.

-(1)-web.jpg?height=200&t=1658967893&width=200)